One of the recent acquisitions was the Mk 32 Torpedo director. It is a sight used by the pilot to drop torpedoes accurately.

Check out the little ship model on the director. The pilot was to align this ship up in the same direction as the ship he was attacking

What is the next best thing to having a MK 32 torpedo director? Having one that was stamped GFE PV-1.

GFE is for Government Furnished Equipment which means the parts that were supplied to the aircraft manufacturer from the Army or Navy. GFE included engines, guns, radios, armament etc. It would be nice to find a director marked for a PV-2 but at least this one went through the Lockheed factory, just a few years before our Harpoon was carved out of aluminum.

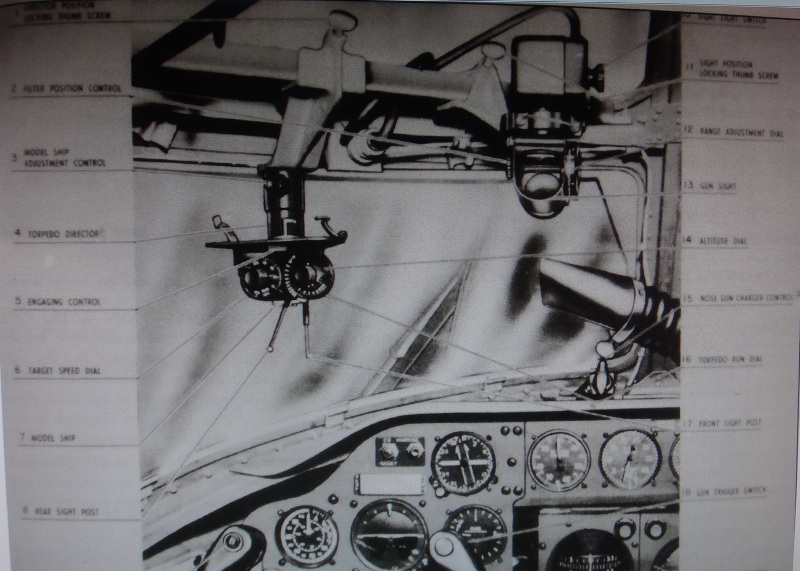

With the torpedo director in hand I have been itching to install it along with the gun sight. Here is the only shot I have found of the Torpedo director installed and the gun sight is on the right

Here is a good shot with the crew in the cockpit and you can see the gun sight in the stowed position.

Another cool shot where the Mk 9 gun sight is visible on the pilots forehead. I guess I will need to find the appropriate dog to recreate this picture!

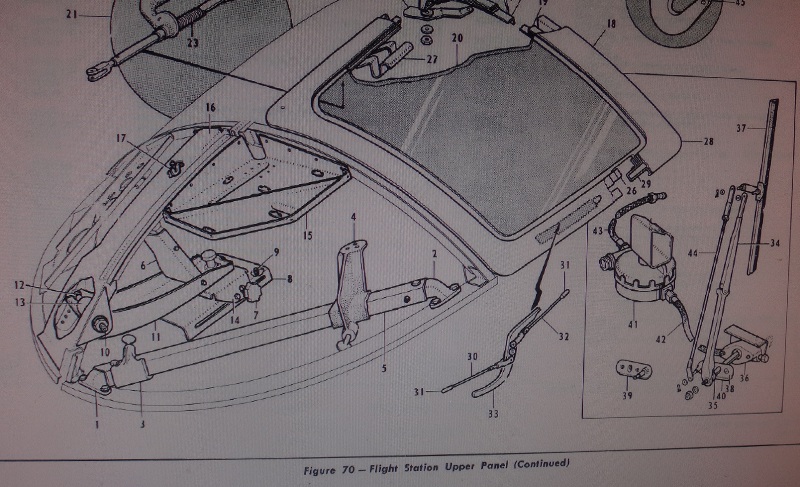

I only have the gun sight mounting bracket, and since I couldn't find the rest of it; the end castings, cross bar and torpedo director bracket will have to be fabricated. In this shot from the parts manual you can see the whole sight bar assembly.

I will need to make items 1,2,4 and 5...and 6 through 17 but that's for another day...

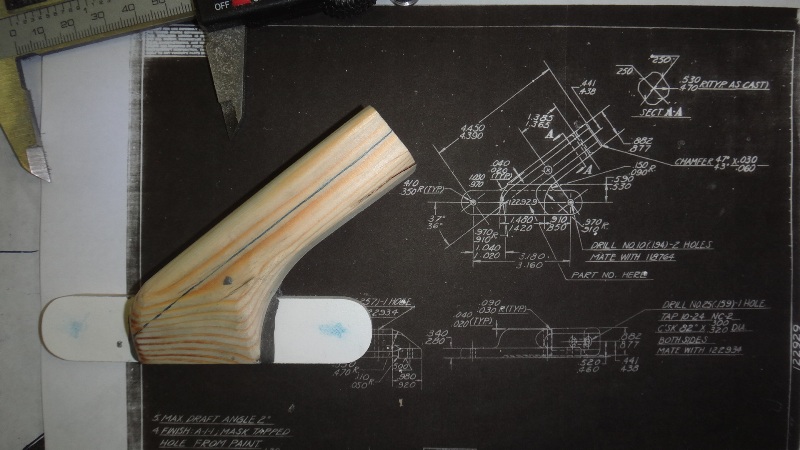

The end mountings and TD brackets are castings so it is time to break out the foundry equipment and re learn the process since it has been a while. Most folks would go right to the CNC and machine one out of a billet of aluminum which is one way to go but machined parts never seem to look quite like the original castings. Besides, the museum has no money to go through the CNC process or have a pattern/casting made elsewhere so we have to do things in house and as cost effectively as possible.

First I need to make a pattern to use as a mold for the casting process. The easiest way is to do make the pattern out of wood. Here is a pattern for one of the ends made from wood and MDF.

The pattern is made oversize to compensate for aluminum shrinkage and my way too coarse sand. I was finally able to use the shrink ruler that has been sitting in the machinist box for way too long. Aluminum shrinks about 3/16 of an inch to a foot so you need to keep this in mind when pattern making. There are shrink rulers made just for pattern making to the scale you need so you will end up with the correct measurements after the parts are cast.

Shrinkage is not so much of a big deal on small parts but I also have to take into account the kind of sand I had to use. Since I was not willing to drive 2 plus hours each way to the Bay Area just to get the proper sand and clay I picked up "fine" sand at the local hardware store and clumping kitty litter for the clay needed to make quick and dirty greensand for casting. This is very crude but it's cheap and readily available for my afternoon project. The next time I need to go to the Bay Area I will pick up the good stuff.

The coarse sand and cat litter makes for real rough surfaces so a lot of sanding will be necessary to clean up the parts.

First the box for the casting process is made up from plywood. Then the pattern is used to make a mold in the sand

Sprue and vent holes are made in the sand which is where the metal will be poured.

Aluminum from various old shop projects was melted down in the electric crucible

And then poured into the mold

The "rough casting" is pulled from the sand. The sprue is sawed off and the clean up process begins. Man, I can't wait to get the proper sand and clay.

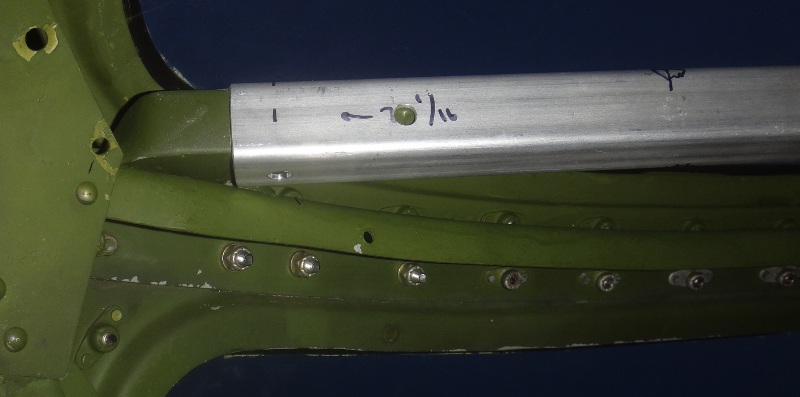

After the parts are cleaned up and painted they are ready for fitting

The assembly is then ready for installation

The only Mark 9 gunsight I had near by was missing the light housing so this one is not complete but it still looks pretty good

Now that I have something to hang it on, It's time to make the mounting bracket for the torpedo director.

_________________

To donate to the PV-2D project via PayPal click here

http://www.twinbeech.com/84062restoration.htmWe brought her from:

to this in 3 months:

Help us get her all the way back

All donations are tax deductible as the Stockton Field Aviation Museum is a 501c3 nonprofit organization. Tell a friend as the Harpoon needs all the help she can get.

Thank you!

Taigh Ramey

Vintage Aircraft, Stockton, California

http://www.twinbeech.com'KEEP ‘EM FLYING…FOR HISTORY!'