Re: T-6 Design Feature Questions

Tue Jul 25, 2023 9:37 am

Noha307 wrote:A third question:

- According to page 128 of Dan Hagedorn's T-6 book:

Dan Hagedorn wrote:There was one additional development of the late AT-6F series. This involved 44-81661, which was assigned for duty as a crosswind landing gear installation test aircraft around 1 December 1950, and it received the designation ET-6F.

(Source: Dan Hagedorn, North American’s T-6: A Definitive History of the World’s Most Famous Trainer (North Branch, MN: Specialty Press, 2009), 128.)

An article by Carol Glines offers additional detail by stating that had "swivel" landing gear.

Does anyone have any more information or pictures about this aircraft? I am quite curious what this could possibly refer to and how an aircraft with such a feature - at least as I can best conceive of it - would actually work.

- Attachments

-

- Capture2.JPG (60.67 KiB) Viewed 7102 times

-

- Capture.JPG (55.55 KiB) Viewed 7103 times

Re: T-6 Design Feature Questions

Sat Sep 23, 2023 3:56 pm

I came across a mention of crosswind landing gear on Beech 18's today:

(Source: Robert K. Parmerter, Beech 18: A Civil & Military History (Tullahoma, Tennessee: Staggerwing Museum Foundation, 2004), 280-281.)

It sounds a bit like the way that the landing gear on the B-52 functions (although that is more akin to the Cessna system described above) - which would make sense since it was designed around the same time. It seems as though in the postwar era there was a concern about how to handle crosswind landings. Naval outlying landing fields during World War II were nothing more than big circles of concrete, which allowed pilots to land from any direction. Before that, back in the days when airfields were truly airfields, the same applied. However, with the recognition that runways were needed and it was impractical to build them in every direction, it seems that aviation was unsure of how to handle the new configurations. (Although some tried this wagon wheel approach. For example, O'Hare or an unnamed New York City airport[1][2].) To be clear, the knowledge of how to perform crosswind landings was there and it was well known that it could be accomplished with training, but this was also an era in which the dream of everyone being able to fly was still seen as valid - just look at the expectations that led to the overproduction and subsequent collapse of the general aviation market in the late 1940s. Furthermore, this notion was predicated on the 1930 era movement to make safety airplanes like the Ercoupe that were "unspinnable" and controlled like automobiles. (Note that, in a footnote for the excerpt below, an Ercoupe was indeed one of the aircraft used in crosswind trials.) Therefore, the idea would have been to design for the lowest common denominator - pilots who would have trouble landing in a crosswind.

Interestingly, the connection with the wagon wheel layout is confirmed by Parmerter:

(Source: Robert K. Parmerter, Beech 18: A Civil & Military History (Tullahoma, Tennessee: Staggerwing Museum Foundation, 2004), 330.)

I have to wonder if any of these landing gear sets survived. It would be quite interesting to look at today. However, if not, Mr. Geisse filed least three patents for his inventions - 2,551,665; 2,557,275 and 2,577,416 - and at least they each include illustrations that provide a basic overview of the principles involved.

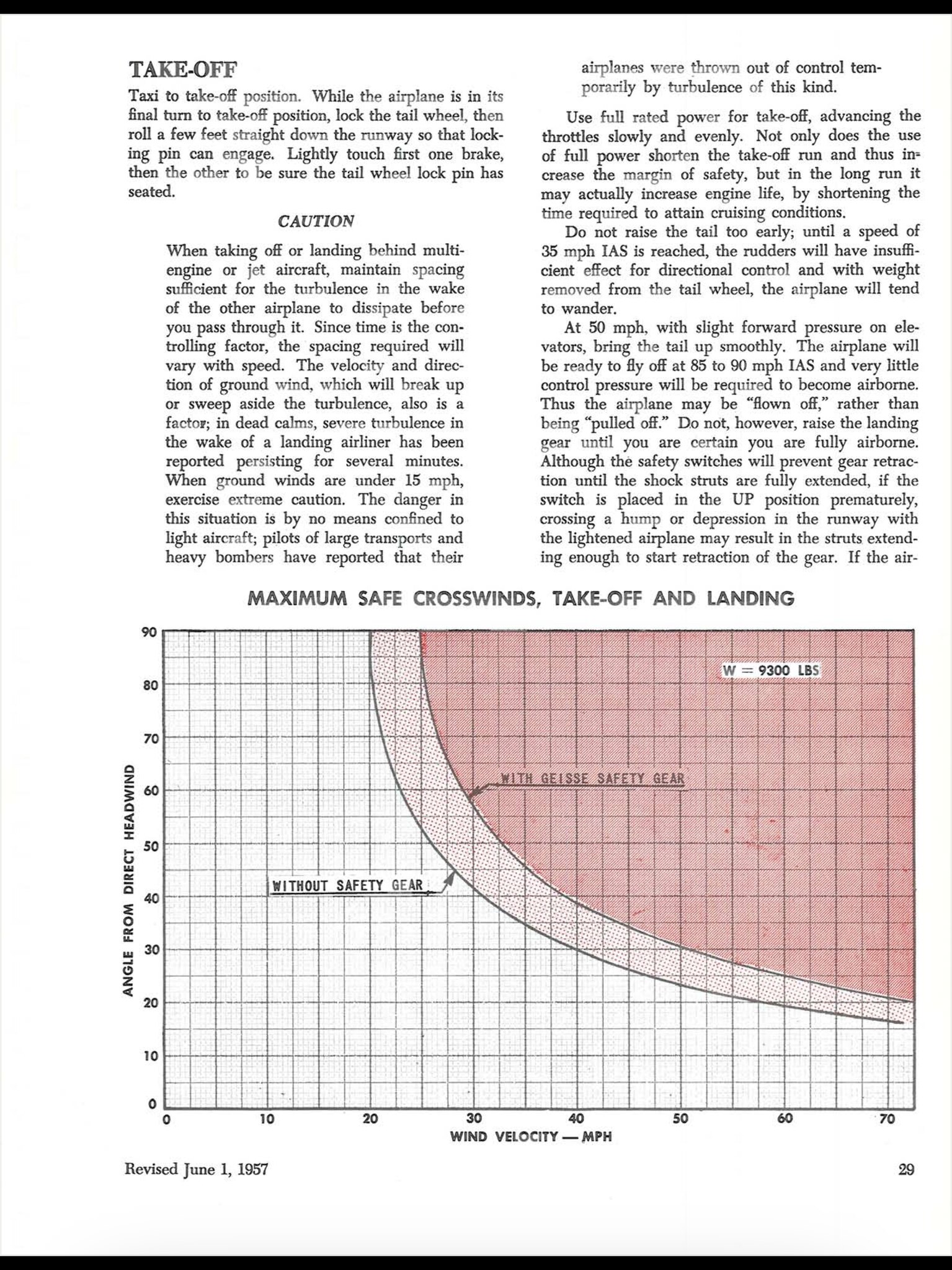

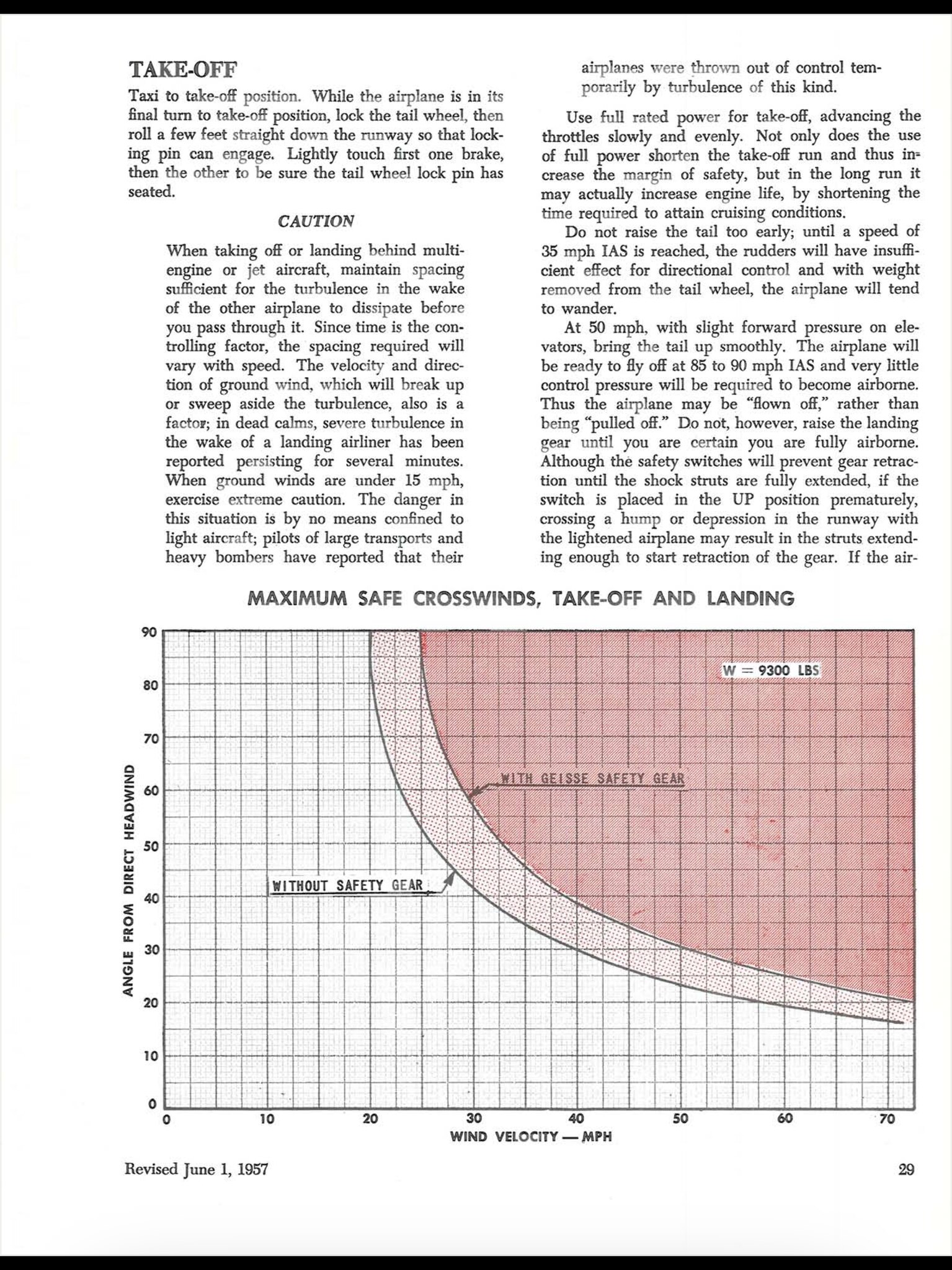

Robert K. Parmerter wrote:In 1956, two more options became available. The first, Geisse Safety Landing Gear, was described as being able to "virtually eliminate crosswind landing problems, a device that permitted each main landing gear wheel to caster outward, under hydraulic and spring control. In a crosswind landing, it automatically and precisely compensated for crab introduced to correct for drift. When the airplane wheels contacted the runway at an angle to the plane's flight path, as in a crosswind landing, the side loads applied to downwind wheel caused it to caster outward. With the wheel castered, the airplane would swing to a heading parallel with its flight path; as the airplane came about, the side loads on the castered wheel were relieved and the wheel returned to its normal alignment." [10.14] Reportedly, on crosswind takeoffs it had no effect except with developing ground-loops; it then assisted in bringing the plane under control by straightening it on a new heading. It acted normally during taxiing or when the plane was pushed or towed. The safety gear weighed 17 lbs. and cost $1,500 if installed at the factory. It consisted of a hydraulic cylinder and piston that replaced the lower leg of the torque knee. A signal light on the instrument panel warned the pilot that a wheel was castered and that the landing gear should not be retracted.

At first, it was a popular option and was ordered for 33 of the next 88 Super 18s.[10.15] This safety gear was developed by John H. Geisse, substantially improving the original work done by All American Aviation (see Chapter 11, AAA Crosswind Landing Gear) and produced under license by Beech. A kit was then offered by Beech for installations on earlier Super 18 and D18S aircraft, but not for the D18S with oleo-leg landing gear. With years of experience on Beechcraft 18s, Nick Quint notes that the Geisse landing gear had two problems, "Pilots thought it was similar to the Cessna cross wind gear, where both wheels caster in the same direction and you touched down in a crab." It wasn't and when you touched down with "this system, only the downwind wheel castered outward. As soon as the upwind wheel touched down, if you didn't square up the airplane first, you were going for a ride! They were also difficult to maintain, so they were often removed and replaced with the solid links."[10.16]

Footnotes10.14: "Geisse Safety Gear, Other New Features Optional on Super 18," The Beechcrafter, June 1956: 2.

10.15: Aviation Week, 24 Dec. 1956: 75.

10.16: Nick Quint, e-mail to the author, 5 Mar. 2001.

(Source: Robert K. Parmerter, Beech 18: A Civil & Military History (Tullahoma, Tennessee: Staggerwing Museum Foundation, 2004), 280-281.)

It sounds a bit like the way that the landing gear on the B-52 functions (although that is more akin to the Cessna system described above) - which would make sense since it was designed around the same time. It seems as though in the postwar era there was a concern about how to handle crosswind landings. Naval outlying landing fields during World War II were nothing more than big circles of concrete, which allowed pilots to land from any direction. Before that, back in the days when airfields were truly airfields, the same applied. However, with the recognition that runways were needed and it was impractical to build them in every direction, it seems that aviation was unsure of how to handle the new configurations. (Although some tried this wagon wheel approach. For example, O'Hare or an unnamed New York City airport[1][2].) To be clear, the knowledge of how to perform crosswind landings was there and it was well known that it could be accomplished with training, but this was also an era in which the dream of everyone being able to fly was still seen as valid - just look at the expectations that led to the overproduction and subsequent collapse of the general aviation market in the late 1940s. Furthermore, this notion was predicated on the 1930 era movement to make safety airplanes like the Ercoupe that were "unspinnable" and controlled like automobiles. (Note that, in a footnote for the excerpt below, an Ercoupe was indeed one of the aircraft used in crosswind trials.) Therefore, the idea would have been to design for the lowest common denominator - pilots who would have trouble landing in a crosswind.

Interestingly, the connection with the wagon wheel layout is confirmed by Parmerter:

Robert K. Parmerter wrote:

In 1947, [All American Aviation] developed and tested a castering crosswind landing gear on a CAA C18S NX74(2), under a research project contract with the CAA.[11.46] The assistant to the Administrator for General Aviation Development of the CAA, John H. Geise, had initiated and directed the investigation of the landing gear, resulting in the CAA/AAA contract. This research was done to determine the need for multidirectional crosswind runways. The gear was successfully demonstrated at Washington National Airport, D.C., on April 15, 1948.[11.47] One month later, a demonstration was given to the Aviation Writers Association in New York City.

The gear's purpose was aiding crosswind landings; the AAA tests were successful, demonstrating that multiple runways were unnecessary. A cost analysis proved that all aircraft then in service could be modified for crosswind operations at a fraction of the cost of building crosswind runways. This led to the CAA Administrator adopting a policy to restrict federal funding for construction of runways specifically for wind coverage. This saved millions in the Federal Airport Program, and Geisse was awarded the 1950 Department of Commerce Gold Medal for "outstanding contribution to the public service and the nation."[11.48]

On January 14, 1949, the crosswind gear was transferred to another CAA C18S, NX219, and six months later it was removed due to "defective clusters on the main spar."[11.49] After leaving government service, Geisse continued to work on crosswind landing gears and "invented and patented an entirely new type which was much simpler, less costly and lighter than any then available. The new type was manufactured under license by the Beech and Cessna airplane companies for both civil and military use."[11.50] The Geisse Safety Landing Gear was offered as an option on production Beechcraft E18S in 1956, and in kit form for use on earlier E18S and D18S aircraft.

[Emphasis added]

Footnotes11.46: Other participants in the CAA crosswind landing gear project were Fairchild on a PT-26; Goodyear on a DC-3 and a Piper J-3; Firestone on an Ercoupe; Bellanca on an Aircruiser; and Northrop on a Pioneer. Scott A. Thompson, "Aircraft of the FAA and Its Predecessors," American Aviation Historical Society Journal 46 1 (Spring 2001): 50.

11.47: Arnold E. Briddon, Ellmore A. Champie and Peter A. Marraine, FAA Historical Fact Book: A Chronology 1926-1971 (Washington, DC: FAA, 1974), 59-60.

11.48: John H. Geisse Papers, Hoover Presidential Library and Museum, http://www.hoover.nara.gov/visiting.html

11.49: The C18S was retired to storage at the CAA Aero Center, Oklahoma City, OK on October 31, 1950. Notes from "CAA Aircraft Registration Records for N219," National Air and Space Museum Project via Dan Hagedorn.

11.50: John H. Geisse Papers.

(Source: Robert K. Parmerter, Beech 18: A Civil & Military History (Tullahoma, Tennessee: Staggerwing Museum Foundation, 2004), 330.)

I have to wonder if any of these landing gear sets survived. It would be quite interesting to look at today. However, if not, Mr. Geisse filed least three patents for his inventions - 2,551,665; 2,557,275 and 2,577,416 - and at least they each include illustrations that provide a basic overview of the principles involved.

Re: T-6 Design Feature Questions

Sat Sep 23, 2023 7:17 pm

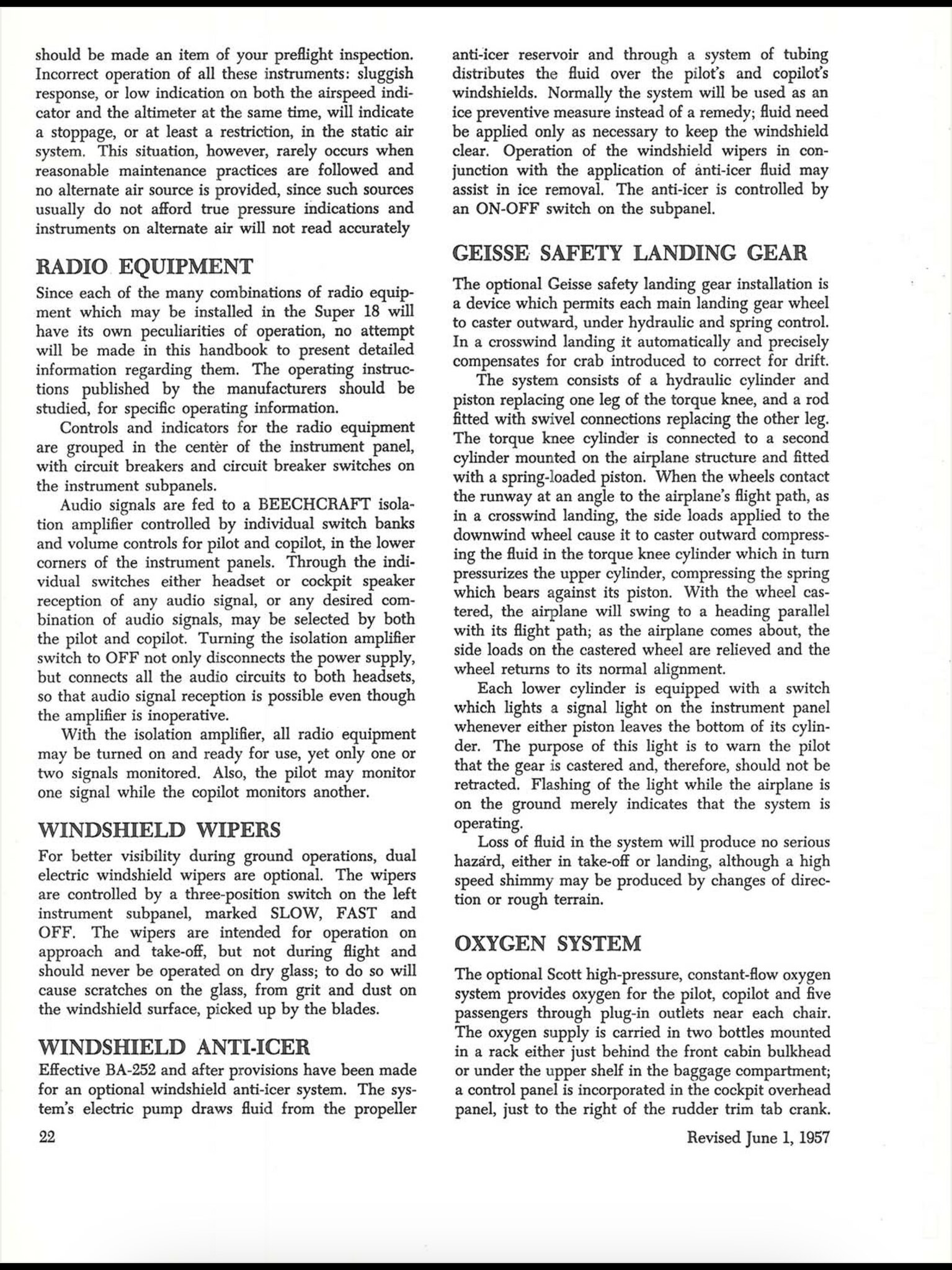

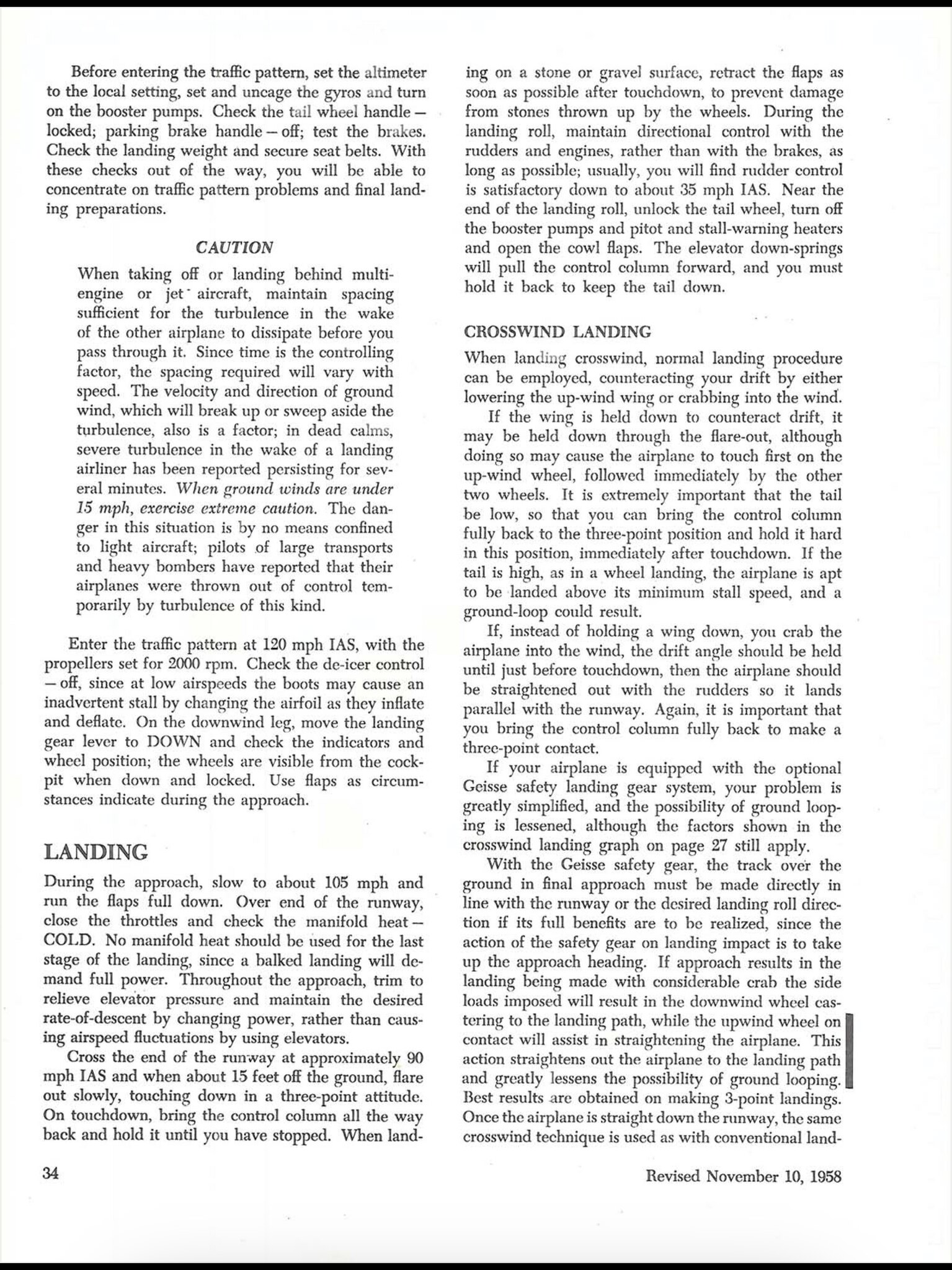

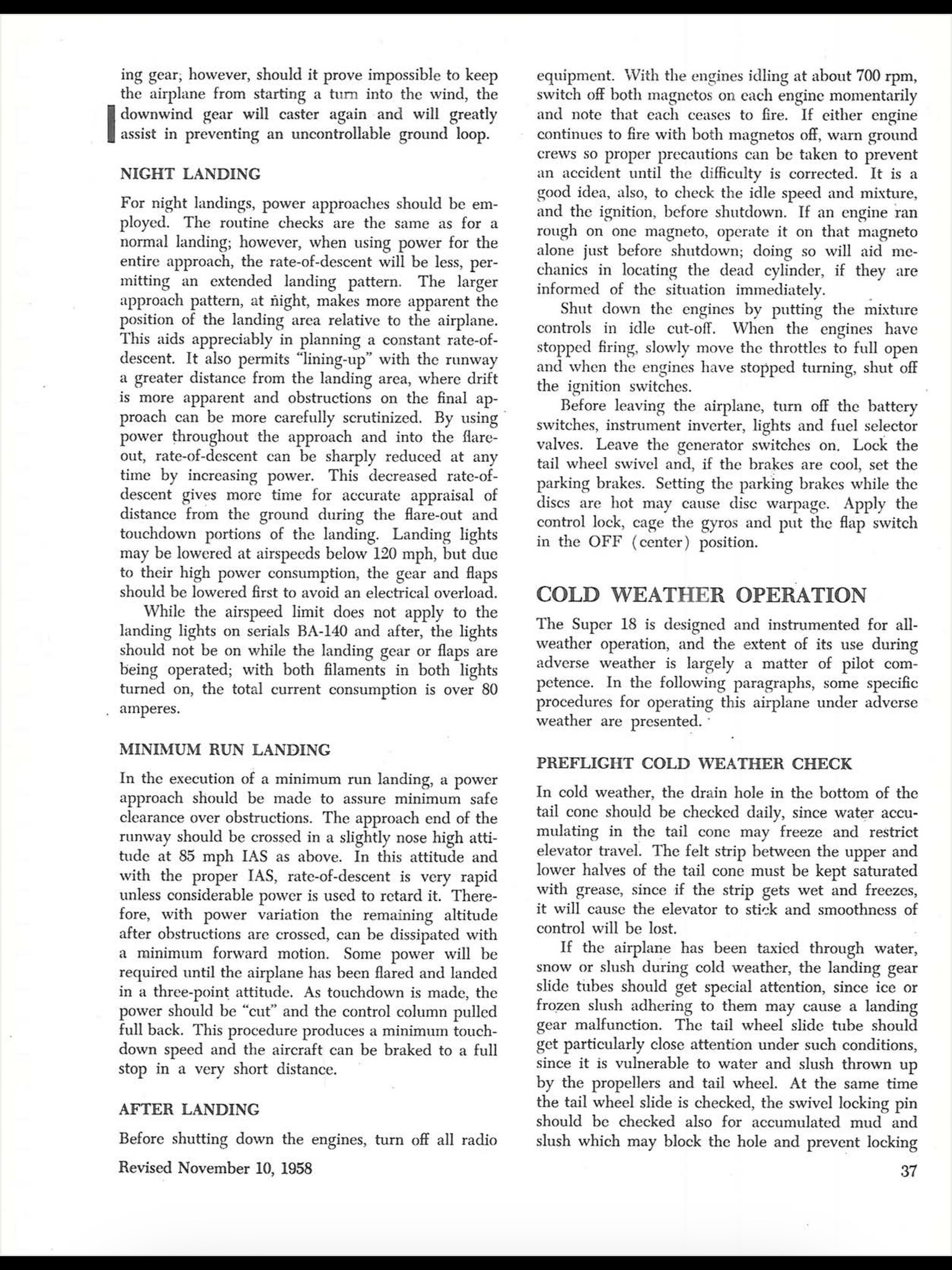

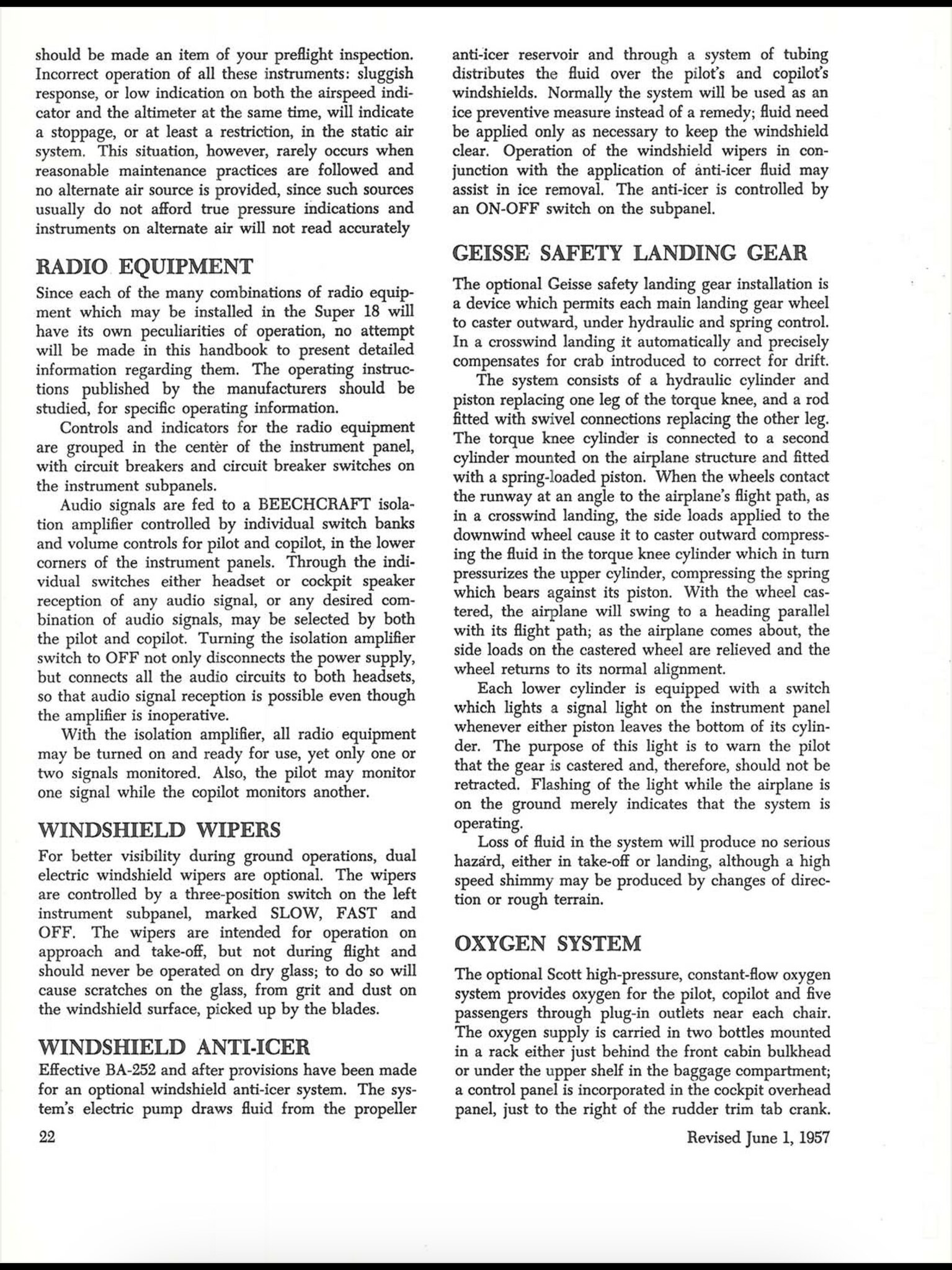

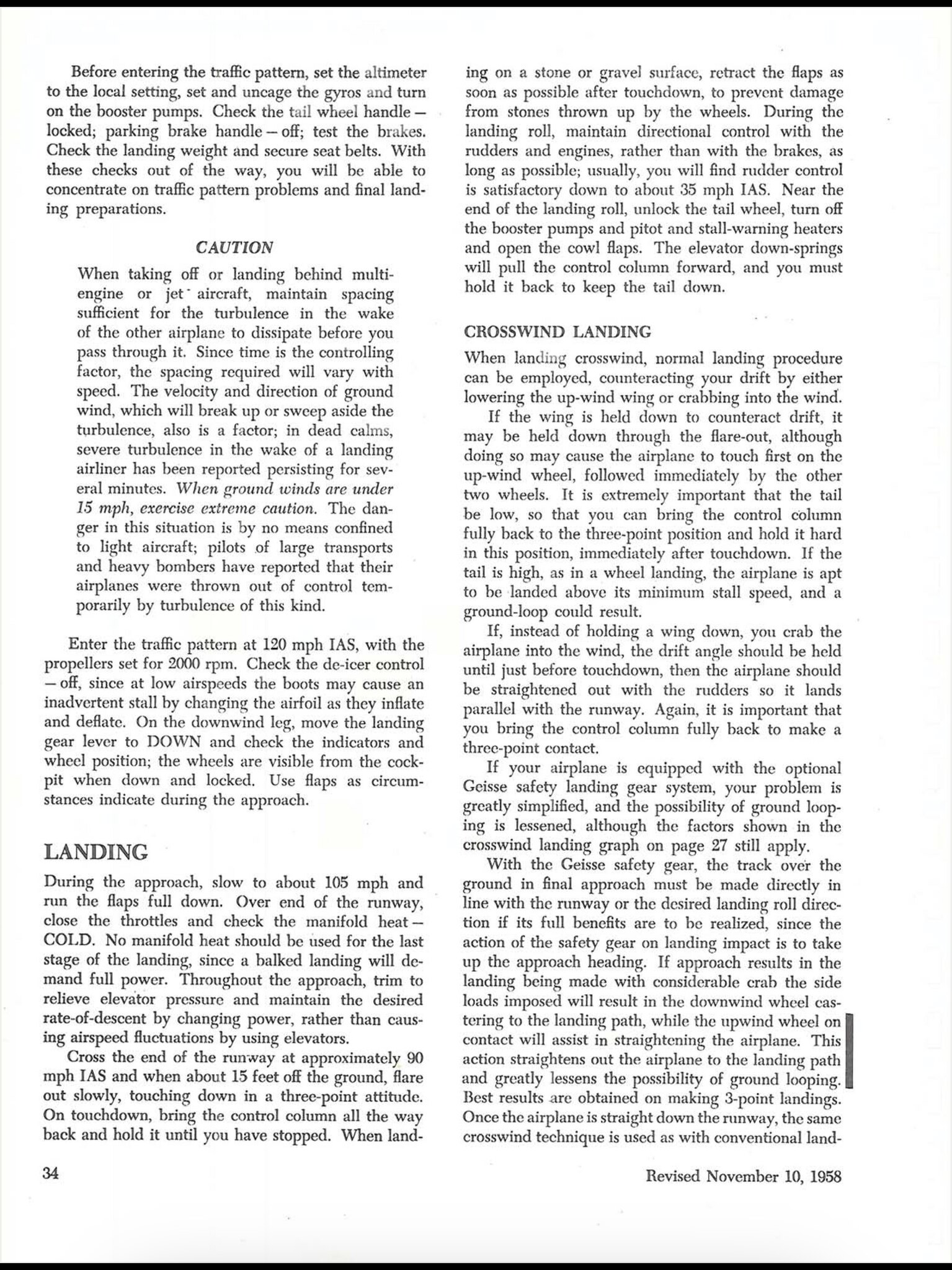

I found this in the Beech Super 18 Flight Handbook from 1958 concerning the Geisse Safety Landing Gear option from the factory.

IMG_3057 by tanker622001, on Flickr

IMG_3057 by tanker622001, on Flickr

IMG_0475 by tanker622001, on Flickr

IMG_0475 by tanker622001, on Flickr

These pages give instructions on using the feature in crosswind landings

IMG_0473 by tanker622001, on Flickr

IMG_0473 by tanker622001, on Flickr

IMG_0474 by tanker622001, on Flickr

IMG_0474 by tanker622001, on Flickr

IMG_3058 by tanker622001, on Flickr

IMG_3058 by tanker622001, on Flickr

IMG_3057 by tanker622001, on Flickr

IMG_3057 by tanker622001, on Flickr IMG_0475 by tanker622001, on Flickr

IMG_0475 by tanker622001, on FlickrThese pages give instructions on using the feature in crosswind landings

IMG_0473 by tanker622001, on Flickr

IMG_0473 by tanker622001, on Flickr IMG_0474 by tanker622001, on Flickr

IMG_0474 by tanker622001, on Flickr IMG_3058 by tanker622001, on Flickr

IMG_3058 by tanker622001, on Flickr

Re: T-6 Design Feature Questions

Thu Apr 18, 2024 1:20 pm

So, apparently at least Corsairs and Dauntless had an "approach light" that was sort of similar in concept to the "landing gear downlock lights" on the T-6 in the sense that they were for the benefit of individuals on the ground (or ship) and not the pilot. However, instead of indicating landing gear position, the approach lights worked like a reverse optical landing system in that the landing signals officer could read them and give feedback to the pilot, rather than the pilot reading a device mounted on the ship:

(Source: Pilot’s Handbook SBD-5 (Douglas Aircraft Company, 30 November 1943), 27, 30.)

However, as described above, the actual implementation resembled more of a PAPI/VASI than the traditional meatball as it depended upon a single light passing through a lens that had different colors at different angles, rather than multiple, single-color lights. In addition to two pictures, an old eBay listing archived on WorthPoint notes that the particular part was "N.A.F. 1024-2":

(Source: WorthPoint)

On the Corsair, it was mounted in the left wing root:

(Source: BritModeller)

It appears that the Flying Heritage Collection's Corsair has one installed:

(Source: HeraldNet)

In light of the discussion of the origins of knockout windows in a recent thread, as well as lines painted on aircraft and passing lights (1, 2) - all features we generally no longer see on aircraft - it is interesting how much more reliant pilots of the time were on visual cues when compared to today. Having just read parts of two books (The Pilot Maker and From Sky to Sea) about Ed Link, it really becomes clear why his trainer was such a revolution and there was such initial skepticism to using it. (cf. The story of him landing at the "socked in" Newark Airport on 10 February 1934 in front of military brass - only 6 days before the first crash in what would become the Air Mail scandal.) None of this is to say that being able to see is not still important to flying or even commonplace, but that the concept of using remote sensing like GPS or ILS or TCAS is much more accepted.

Pilot's Handbook SBD-5 wrote:Approach Light

The Type 1-A approach light in the leading edge

of the left wing operates in conjunction with the

arresting hook.

When the arresting hook is extended, the ap-

proach light automatically illuminates and indicates

to the signal office [sic] the attitude of the airplane in

regard to carrier landing as follows: red light, too

low; green light, too high; amber light, correct approach.

When landing on an airfield (arresting hook

retracted), the approach light may be operated by

the switch on the pilot's electrical panel (Item 8,

Page 29.

(Source: Pilot’s Handbook SBD-5 (Douglas Aircraft Company, 30 November 1943), 27, 30.)

However, as described above, the actual implementation resembled more of a PAPI/VASI than the traditional meatball as it depended upon a single light passing through a lens that had different colors at different angles, rather than multiple, single-color lights. In addition to two pictures, an old eBay listing archived on WorthPoint notes that the particular part was "N.A.F. 1024-2":

(Source: WorthPoint)

On the Corsair, it was mounted in the left wing root:

(Source: BritModeller)

It appears that the Flying Heritage Collection's Corsair has one installed:

(Source: HeraldNet)

In light of the discussion of the origins of knockout windows in a recent thread, as well as lines painted on aircraft and passing lights (1, 2) - all features we generally no longer see on aircraft - it is interesting how much more reliant pilots of the time were on visual cues when compared to today. Having just read parts of two books (The Pilot Maker and From Sky to Sea) about Ed Link, it really becomes clear why his trainer was such a revolution and there was such initial skepticism to using it. (cf. The story of him landing at the "socked in" Newark Airport on 10 February 1934 in front of military brass - only 6 days before the first crash in what would become the Air Mail scandal.) None of this is to say that being able to see is not still important to flying or even commonplace, but that the concept of using remote sensing like GPS or ILS or TCAS is much more accepted.

Re: T-6 Design Feature Questions

Mon Apr 22, 2024 7:58 pm

As a follow up on crosswind landing gear, I went on a tour of NMUSAF today and the guide pointed out that the Blériot XI actually had such a feature:

(Source: PBS)

(Source: PBS)