After the Arizona gang departed Steve, Ricky, Syd and Caleb worked at cleaning out the airframe.

We flushed the oil system with avgas running through a transfer pump and a filter to clean and catch the debris. Then the lines were blasted with the steam cleaner to make sure the contaminates were completely removed. Many hard lines were removed and checked and all was good. This is Steve steam cleaning the firewall and oil system lines

Here work begins on the oil tank. After draining and flushing it was removed for a real cleaning

The oil tank was just like one of the Gold Rush type of TV reality shows in that we we flushed the tank the heavy metal settled in the ripples of the rubber self sealing tank. This was a new old stock tank that was installed back when we were prepping for Oshkosh. Here you can see lots of silver all over the bottom of the tank. You should see what the filter looked like. That would make for a good post all by itself.

All clean and ready to go back in

The prop was in need of disassembly and cleaning to get the metal out but also it was almost due for the AD compliance. The AD or Airworthiness Directive is for an inspection for corrosion on the prop blade shanks. This needs to be accomplished every 5 years if no corrosion is found. Our props sit outside so this can be a real problem.

The props are disassembled and cleaned and the teflon anti friction strips are removed and the blade shanks are inspected. They were beautiful with no corrosion present. The blades are like new and are full dimension in every aspect.

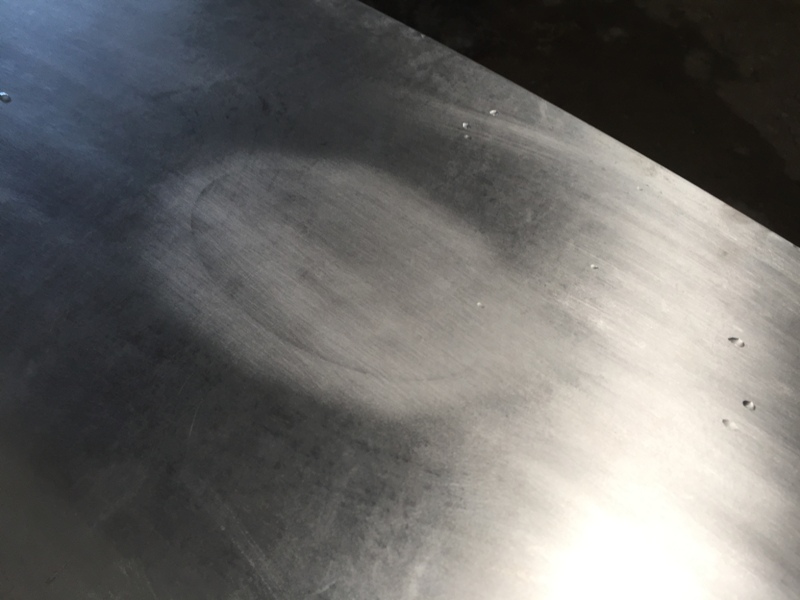

This shot was taken just after the outer barrel half was removed. The prop can act like a centrifuge where heavy particles and dirt tends to seperate out and build up near the blade shanks. If moisture is in the oil or condensation in the prop it can concentrate around the blade shanks and cause the corrosion that the inspection is looking for. Another good part of the AD is that these props will be cleaned at least every 5 years which is a good thing. Desludging annually is the best way to go

The props are paint stripped and inspected and prepared for the new teflon strips.

For all of you rivet counters and serial number junkies out there I found a couple of interesting items. These blades which are 6477A-12's were build under an Army contract with W535 stamps. Why would the Navy prop (6477A-12's used only with Venturas and Harpoons) have Army markings? Sure the B-34 might have been a possibility but I wouldn't have expected this. Also the original hamilton standard decal positions were visible under the paint. You can even make out the Remington Rand part of the decal since these blades were made by them and have RR serial numbers. I wouldn't have expected to see markings like the decals were applied directly to the blade as I assumed that they would have been applied over the black painted blades thus not leaving their mark on the bare aluminum.

Since the 6477 blades are used on C-47's, B-24's and B-17's I guess they could have been built for those contracts and then diverted to the Navy and cut down for the Ventura/Harpoon production.

I am also amazed that these are the same blades used on C-47's, B-17's and B-24's propellers and yet they were cut down 6 to 12 inches. Same exact 3 blade propeller yet cut down in diameter quite a lot and used on an engine that has 800 to 1000 more horsepower. It's all in the nose case gearing I know but wow. To look at the prop on the same basic engine on a B-26, C-46 or P-47 and look at the massive difference between their prop at 14-15 foot diameter and four blades and the Harpoon/Ventura 3 blade prop at 11 foot diameter.

Interesting.

Here are the blade shanks being prepped for the corrosion barrier and teflon anti friction strips

The engine is ready to hang on the firewall so Sydney and Steve did just that

Good job guys. Now we need to hook it all up

_________________

To donate to the PV-2D project via PayPal click here

http://www.twinbeech.com/84062restoration.htmWe brought her from:

to this in 3 months:

Help us get her all the way back

All donations are tax deductible as the Stockton Field Aviation Museum is a 501c3 nonprofit organization. Tell a friend as the Harpoon needs all the help she can get.

Thank you!

Taigh Ramey

Vintage Aircraft, Stockton, California

http://www.twinbeech.com'KEEP ‘EM FLYING…FOR HISTORY!'