Re: Shackleton WR963 engine runs

Wed Oct 13, 2010 5:08 pm

Hi all,

Forgive me for being a little intermittant with these updates, like a lot of us volunteers on here the day job gets in the way.

The fly-in at Coventry airport went well! It was really refreshing to have big crowds around the Shack and even if she hadn't actually flown in; the atmosphere was great.

We had her open at 9am, and from that point onwards we had a full aircraft, and a good queue all day! None of the team got more than a half hour break, and we finally managed to close at 5.30pm after all the cadets, fire crews, police had been for a look.

We estimate we must have had about 500 people through the aeroplane and we only had to upset one person who thought it was great fun to start flicking switches (including the magneto switches amongst others... idiot..). Sorry to say he was a visitor from the US and didn't seem to think the signs applied to him as he "was a flier"... Needless to say, he was shown the door.

Other than that it was a great event with loads of money raised for charity (Help for Heroes... a charity for wounded servicemen) and we even had a visit from another big Avro:

One of the major jobs we needed to do the following week was move the scaffolding from around the starboard wing. It's usefulness is over at that side, and it dissuades people from visiting us. We got it all down and packed away, and 963 looks a lot happier for it.

Things are coming on in leaps and bounds with the pre-oilers. No 1 and 2 have their pumps fitted, and 3 and 4 will have them on within a week or so. Our electrician was quite perplexed to find that they didn't work first time, but it turned out to be nothing more than a really thorough job done by the RAF when they removed the oil dilution system. Every junction, fuse and connection was disconnected and capped. When the last ones were found the pump on No 1 buzzed away sounding really healthy. It looks as if we'll be running again before Christmas, which keeps us on schedule.

We're looking at having the props built up by an outside company, as none of us have done it before and don't feel happy doing it from scratch. We will be visiting whoever does it, to see how its done and hopefully to start to learn.

The scaffolding being up had also prevented us from opening the bomb doors all the way. They need to be exercised on a regular basis to keep the hydraulic rams happy. Seeing as we haven't moved them since January, now was as good as ever... so with the electrical power on, and bomb doors "open" selected, we just need hydraulic pressure.

Which was when I found people looking my way! So, up into the starboard undercarraige bay I got, and started yanking on the handpump.

That's it, top just right of centre of the pic. The spar raps your knuckles as you pump, the handle's not quite big enough to get a big swing on, and high enough up to make you teeter on the undercarraige footpegs. The pressure on the handle is akin to trying to jack up a very heavy car. After a reasonable amount of time,the doors were fully open and I was free to collapse out of sight. (I work behind a desk. I'm not into this fitness lark)

We've done some more painting along the fuselage, and around the tail

You can see we have the first coat of white on, but we still need to do up the port side, and underneath. Under the tail particularly, as the camera bay doors don't look great and may need some attention before we paint them. We also need to do a bit of cleaning under there too, which is made more difficult when the ground is wet. We'll get there though... what you must remember is that by only working one day per week, this is only the SEVENTH day of actually putting paint on the aircraft, and the weathers not helping at all.

Still loads to do though!

Regards,

Ric

Forgive me for being a little intermittant with these updates, like a lot of us volunteers on here the day job gets in the way.

The fly-in at Coventry airport went well! It was really refreshing to have big crowds around the Shack and even if she hadn't actually flown in; the atmosphere was great.

We had her open at 9am, and from that point onwards we had a full aircraft, and a good queue all day! None of the team got more than a half hour break, and we finally managed to close at 5.30pm after all the cadets, fire crews, police had been for a look.

We estimate we must have had about 500 people through the aeroplane and we only had to upset one person who thought it was great fun to start flicking switches (including the magneto switches amongst others... idiot..). Sorry to say he was a visitor from the US and didn't seem to think the signs applied to him as he "was a flier"... Needless to say, he was shown the door.

Other than that it was a great event with loads of money raised for charity (Help for Heroes... a charity for wounded servicemen) and we even had a visit from another big Avro:

One of the major jobs we needed to do the following week was move the scaffolding from around the starboard wing. It's usefulness is over at that side, and it dissuades people from visiting us. We got it all down and packed away, and 963 looks a lot happier for it.

Things are coming on in leaps and bounds with the pre-oilers. No 1 and 2 have their pumps fitted, and 3 and 4 will have them on within a week or so. Our electrician was quite perplexed to find that they didn't work first time, but it turned out to be nothing more than a really thorough job done by the RAF when they removed the oil dilution system. Every junction, fuse and connection was disconnected and capped. When the last ones were found the pump on No 1 buzzed away sounding really healthy. It looks as if we'll be running again before Christmas, which keeps us on schedule.

We're looking at having the props built up by an outside company, as none of us have done it before and don't feel happy doing it from scratch. We will be visiting whoever does it, to see how its done and hopefully to start to learn.

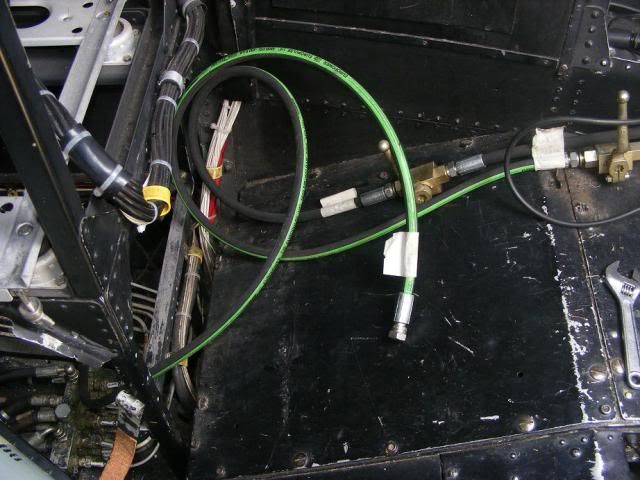

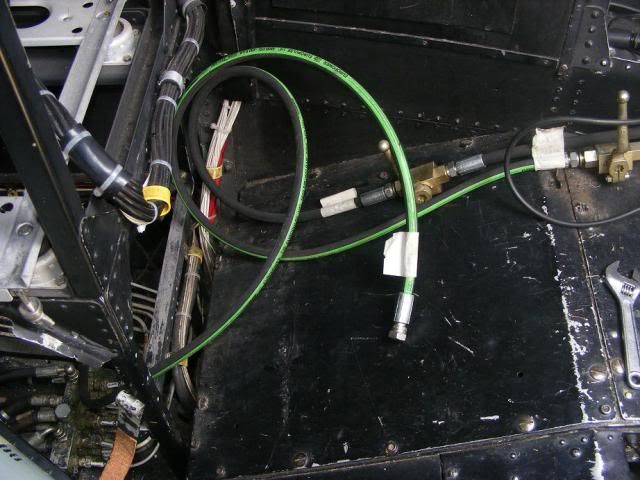

The scaffolding being up had also prevented us from opening the bomb doors all the way. They need to be exercised on a regular basis to keep the hydraulic rams happy. Seeing as we haven't moved them since January, now was as good as ever... so with the electrical power on, and bomb doors "open" selected, we just need hydraulic pressure.

Which was when I found people looking my way! So, up into the starboard undercarraige bay I got, and started yanking on the handpump.

That's it, top just right of centre of the pic. The spar raps your knuckles as you pump, the handle's not quite big enough to get a big swing on, and high enough up to make you teeter on the undercarraige footpegs. The pressure on the handle is akin to trying to jack up a very heavy car. After a reasonable amount of time,the doors were fully open and I was free to collapse out of sight. (I work behind a desk. I'm not into this fitness lark)

We've done some more painting along the fuselage, and around the tail

You can see we have the first coat of white on, but we still need to do up the port side, and underneath. Under the tail particularly, as the camera bay doors don't look great and may need some attention before we paint them. We also need to do a bit of cleaning under there too, which is made more difficult when the ground is wet. We'll get there though... what you must remember is that by only working one day per week, this is only the SEVENTH day of actually putting paint on the aircraft, and the weathers not helping at all.

Still loads to do though!

Regards,

Ric

Re: Avro Shackleton WR963

Wed Oct 13, 2010 5:50 pm

Great job guys ! Good to see you are saving this old bird !

Re: Avro Shackleton WR963

Wed Oct 13, 2010 6:32 pm

Apologies on behalf of the Yank who started flipping switches....sometimes, no matter where they are, they just don't know any better....and from a 'flyer', to boot. He should know better. I was in that plane and did'nt touch a switch, I did'nt know if the plane was 'live' or not at that point.

Mark

Mark

Re: Avro Shackleton WR963

Wed Oct 13, 2010 7:48 pm

Thank you for the updates and photos. Much appreciated.

Kevin

Kevin

Re: Avro Shackleton WR963

Thu Oct 14, 2010 2:14 am

corsair166b wrote:Apologies on behalf of the Yank who started flipping switches....sometimes, no matter where they are, they just don't know any better....and from a 'flyer', to boot. He should know better. I was in that plane and did'nt touch a switch, I did'nt know if the plane was 'live' or not at that point.

Mark

Mark

No need to apologise for him. There's always one at any show who thinks they can do as they please... I've read the thread "Airshow Horror Stories" so I knew it happens.

Glad to hear you came to visit us though, I hope you enjoyed it!

Regards,

Ric

Re: Avro Shackleton WR963

Thu Oct 14, 2010 9:29 am

Richard....love the place...and maybe you know one of my friends there, Steve Bridgewater, newly married (shhhh...to a WELSH girl)....he was giving me so much crap for being Welsh and he goes and marries one....tell him I said HI if you see him...

Mark

Mark

Re: Avro Shackleton WR963

Thu Oct 14, 2010 2:01 pm

Mark,

It is quite a place what with all the 1950's aircraft. I'm usually there until its too dark to work!

I've spoken with Steve once or twice by e-mail, but I've yet to meet him! He is the commercial manager of Airbase, and one of these days I intend to take him up on his offer of a coffee and a chat. Always seems to be that when I'm there, he's not and vice versa. I guess he's a very busy man.

When I see him I promise I'll pass on your message.

Ric

It is quite a place what with all the 1950's aircraft. I'm usually there until its too dark to work!

I've spoken with Steve once or twice by e-mail, but I've yet to meet him! He is the commercial manager of Airbase, and one of these days I intend to take him up on his offer of a coffee and a chat. Always seems to be that when I'm there, he's not and vice versa. I guess he's a very busy man.

When I see him I promise I'll pass on your message.

Ric

Re: Avro Shackleton WR963

Mon Feb 07, 2011 6:19 am

Hi all,

I thought I'd drop in and give you an upate on the old Shacklebomber!

Winter in England has been fairly harsh so far, and working outdoors has been no fun in freezing temperatures, but we have pushed on with the work. Ther has been more than once we've had to use the ditching hatches to get into her because the crew door lock has frozen solid!

The Griffon camshaft work has all been done, and the oil priming setup completed. It misbehaved the first couple of times we tested it, this was eventually traced to an adapter in the feed line being too restrictive in bore size. It made the oil pressure go off the gauge, but very little actually got to the engine. We've amended our pre-oiling checks to include pulling the props through while the pump is running, so the cams get a really good feed before we even attempt to fire an engine up. 4 minutes per engine means our little crew's fitness is now improving somewhat...

The painting has halted temporarily as with the ice and damp, it's counter productive to continue. We're hoping to borrow a brief spell in a hangar before long to finish it off, the target date to have it finished is April when 'Airbase' opens again.

We've had some nice little bits of airframe work progressing, with lots of the under wing access hatches getting attention, some of them haven't been opened in years and are responsible for the last bit of binding in the flight controls. We've traced a seized trim tab system out to inside the wing, so it's become a priority to get in there.

The stubborn hatches are having their screws drilled out and retapped, and they are all getting a good dose of the necessary anti-seize compound on the new screws, though its taking a while as there's around 60 hatches under each wing. Round at the back of the aircraft saw work on re-sealing the camera bay doors, and the damaged trim tab we had on the port tail fin has been de-riveted, repaired and refitted. With the re-sealing work, we added it up and have used some 350 yards of the stuff!

The best part now however; we've now reached a point where we can wake 963 up again! On 5th Feb, we connected the ground power unit, pre-oiled and got the crew aboard...

She lives!

After 12 months of sitting and various things having been disconnected, drained and the like, the first engine we tried (No3) was a little bit grumpy. Second attempt at starting got it and it didn't take long to settle down and run lovely and smooth! No4 put up even less of a fuss.

We ran them up individually and checked all the temps and pressures and they behaved very well. We went through all the other systems apart from the pneumatics (currently unserviceable) cycling the bomb doors, the flaps, and testing just about everything on board.

The list of snags was surprisingly small!

Some minor electrical lighting issues, and an external intercom connection dead. Not bad for an old aeroplane that has sat outside for 20 years, in all weathers.

We're now turning our attention to the port side to get No1 and No2 running. No1 needs attention to its priming system - while we have managed to stop the evil rain water creeping into the fuselage and wing structure, it found a new place to hide. Not a good place either, it being inside the Port No 1 fuel tank. I found the first lot, being quite disturbed when with all the other tanks showed good blue coloured fuel from the drains, this one produced vast quantities of colourless, odourless (and tasteless..) liquid. Close to 6 litres of water have been drained from it, and it had made its way into the line and priming pump.

It looks as if its been caught just in time, and investigations are ongoing as to how its getting in. The tank cap recesses have been taped up for the moment as they're the prime suspect. No2 is a bit simpler, it's just awaiting a prop specialist to work his magic and turn the six freshly overhauled blades and translation unit into something resembling a contra rotating propeller!

As mentioned earlier we also have to rebuild the pneumatics air crate as the bottles are well out of date. One of them said on the side "Next Insp 7.61" so we took them out rather than risk 700psi in four bottles of unknown age and condition. The brakes, and radiator shutters are all pneumatic which are services we need sooner rather than later, so if the bottles pass inspection they'll be back in before long.

so we took them out rather than risk 700psi in four bottles of unknown age and condition. The brakes, and radiator shutters are all pneumatic which are services we need sooner rather than later, so if the bottles pass inspection they'll be back in before long.

The old Shackleton's future is looking very bright, and it deserves to be. This is her 20th year in retirement (she was front line operational until 1990!), and the crew looking after her has changed a lot. It's slowly changing over from those who worked on her in service, to those of us who remember her twilight years as kids. The average age of the crew is now just below 30, and for those of us being trained to maintain and operate this old beast it's mind-blowing. The engine run has reminded us just how fortunate we all are to be looking after a piece of living history.

Hopefully I'll have some more pictures and video of the run to add soon.

Regards,

Rich

I thought I'd drop in and give you an upate on the old Shacklebomber!

Winter in England has been fairly harsh so far, and working outdoors has been no fun in freezing temperatures, but we have pushed on with the work. Ther has been more than once we've had to use the ditching hatches to get into her because the crew door lock has frozen solid!

The Griffon camshaft work has all been done, and the oil priming setup completed. It misbehaved the first couple of times we tested it, this was eventually traced to an adapter in the feed line being too restrictive in bore size. It made the oil pressure go off the gauge, but very little actually got to the engine. We've amended our pre-oiling checks to include pulling the props through while the pump is running, so the cams get a really good feed before we even attempt to fire an engine up. 4 minutes per engine means our little crew's fitness is now improving somewhat...

The painting has halted temporarily as with the ice and damp, it's counter productive to continue. We're hoping to borrow a brief spell in a hangar before long to finish it off, the target date to have it finished is April when 'Airbase' opens again.

We've had some nice little bits of airframe work progressing, with lots of the under wing access hatches getting attention, some of them haven't been opened in years and are responsible for the last bit of binding in the flight controls. We've traced a seized trim tab system out to inside the wing, so it's become a priority to get in there.

The stubborn hatches are having their screws drilled out and retapped, and they are all getting a good dose of the necessary anti-seize compound on the new screws, though its taking a while as there's around 60 hatches under each wing. Round at the back of the aircraft saw work on re-sealing the camera bay doors, and the damaged trim tab we had on the port tail fin has been de-riveted, repaired and refitted. With the re-sealing work, we added it up and have used some 350 yards of the stuff!

The best part now however; we've now reached a point where we can wake 963 up again! On 5th Feb, we connected the ground power unit, pre-oiled and got the crew aboard...

She lives!

After 12 months of sitting and various things having been disconnected, drained and the like, the first engine we tried (No3) was a little bit grumpy. Second attempt at starting got it and it didn't take long to settle down and run lovely and smooth! No4 put up even less of a fuss.

We ran them up individually and checked all the temps and pressures and they behaved very well. We went through all the other systems apart from the pneumatics (currently unserviceable) cycling the bomb doors, the flaps, and testing just about everything on board.

The list of snags was surprisingly small!

Some minor electrical lighting issues, and an external intercom connection dead. Not bad for an old aeroplane that has sat outside for 20 years, in all weathers.

We're now turning our attention to the port side to get No1 and No2 running. No1 needs attention to its priming system - while we have managed to stop the evil rain water creeping into the fuselage and wing structure, it found a new place to hide. Not a good place either, it being inside the Port No 1 fuel tank. I found the first lot, being quite disturbed when with all the other tanks showed good blue coloured fuel from the drains, this one produced vast quantities of colourless, odourless (and tasteless..) liquid. Close to 6 litres of water have been drained from it, and it had made its way into the line and priming pump.

It looks as if its been caught just in time, and investigations are ongoing as to how its getting in. The tank cap recesses have been taped up for the moment as they're the prime suspect. No2 is a bit simpler, it's just awaiting a prop specialist to work his magic and turn the six freshly overhauled blades and translation unit into something resembling a contra rotating propeller!

As mentioned earlier we also have to rebuild the pneumatics air crate as the bottles are well out of date. One of them said on the side "Next Insp 7.61"

The old Shackleton's future is looking very bright, and it deserves to be. This is her 20th year in retirement (she was front line operational until 1990!), and the crew looking after her has changed a lot. It's slowly changing over from those who worked on her in service, to those of us who remember her twilight years as kids. The average age of the crew is now just below 30, and for those of us being trained to maintain and operate this old beast it's mind-blowing. The engine run has reminded us just how fortunate we all are to be looking after a piece of living history.

Hopefully I'll have some more pictures and video of the run to add soon.

Regards,

Rich

Re: Avro Shackleton WR963

Mon Feb 07, 2011 12:47 pm

This is fantastic! Keep up the great work.

Re: Avro Shackleton WR963

Tue Feb 08, 2011 2:23 pm

You guys have alot of work to do.Go guys! Good luck ,I'll be rooting for you and be thankful that the stupid"Yank" didnt flip the landing gear lever. I think that I read somewhere that the Yank's name was Bozo the clown. I think I read that on the Flypast website

I could be wrong,I have been before in the past.

I could be wrong,I have been before in the past.

Re: Avro Shackleton WR963

Mon Apr 11, 2011 6:08 am

Hi all!

Well, we finally got lucky with the old Shackleton, being given some hangar time to get the painting done (more of which later) thanks to the kindness of Classic Flight at Coventry. They moved several of their collection out into the cold for a few nights including this funny looking US built thing:

Howard 500 N500LN...

Anyway... back to things with the proper number and arrangement of engines.

Wall to wall sunshine over the past few weeks let us make progress on the prep work for the paint, and not a moment too soon. All the team have been working from dawn to dusk every day they can - with some of the guys going to the airport in the evenings, going away from the aircraft exhausted but happy.

963 was made ready for moving (she has to shuffle over a bit soon anyway to make room for DC-6 G-SIXC to get past into its new position) the dates for the hangar being set at 24 - 27 March. We were to have a a four day paintathon, the intention being to only have roundels and stencils left to do afterward.

I thought I was prepared for it... I really wasn't. From the first e-mails last night saying 963 was in the hangar a day early, everything went nuts. I loaded up the car with as much painting materials as I could the following morning and set off for Coventry, eager to see what was going on there. I couldn't believe how busy the place was... it seemed as if everything was being worked on at once. Classic Flight/Airbase's second season is going to be a cracker.

The paintathon..

Arriving to find everything sunny and bright I made my way over to where the Shackleton now wasn't, to drop the paint supplies off. I'm sure this was where we left it?

Best go look inside then. There she is!! Asking around the place and a figure of 17 years was arrived at since she last saw the inside of a hangar.

Two of our guys were already hard at work starting to mask up the windows and cover the floor, as was requested of us. The team are all in good spirits, even when asked to unroll the plastic floor covering again (and again) for the camera..

The ground handlers were superb, putting 963 in the hangar bang on the centre line with barely feet to spare on the wingtips. This is how close it was:

As you can see it's a snug fit.

Helping out with the masking, I had to take this shot, as it was too good to miss:

The DC3 was started up later in the afternoon outside, and made a really very pleasing amount of noise. :diablo:

Being at the west end of the hangar meant we got the sunshine for longer, which was rather nice. 963 looked that happy in there it was rather tempting to let the tires down so we don't have to move out, squat in the aircraft, or just paint a line on the floor that's Shackleton shaped with a "reserved" sign on it...

Saturday we worked long into the night, pausing only briefly for food and once in shock, when one of the female members of our painting team dropped into conversation that she was a pole dancing instructor...

Unfortunately we got beaten by time, WR963 wasn't finished. Various small leaks caused problems with contaminating paint.Then the paint we had for the roundels/fin flashes started reacting, so they were redone the following week. Luckily we noticed it after the first fin flash, so we didn't have to worry about any large areas. We overestimated the need for some colours, and underestimated others, but on the whole she's about 90% done.

These last two were taken right before we left.

WR963 was pushed out on 30th March, after 7 days indoors, and some of our gang were down there to see it happen. Still a bit more to do, but this picture was too good not to miss.

Two weeks later and other than the long standing issue of No 2's propeller, she looks smashing. I'm not going to post pictures for now, as we've decided to try and roll out the finished article for Airbase first day of business this year, so we promised to hold any photo's until then..

963 now wears the national markings, her squadron codes and emblems. The stenciling is getting done, and we'll have the most noticeable bits done by the time the public see her for the first time. Walkways, drain points, emergency markings... even in plain white and grey a Shackleton is a colourful beast up close.

The only pain with the paint is the underwings - despite best efforts, it's still slow going under there, so she won't be wearing the underwing serial numbers for a couple of weeks yet. The biggest reason being while we stopped things leaking into 963, there's still a few leaks out. We'll get to the bottom of them though.

In terms of crew numbers, we had around 20 people working on the Shackleton over the painting weekend, which is kind of a record for us. Even the elder members of the group can't remember seeing that many people working on her in the 12 years that she has been in their care. It's all good as the average on a normal day now is between 10 and 15 members, making large tasks that much easier. The ever growing "list" is now being fought to a standstill, and within a short time it's going to start getting smaller.

We've had two of the badly clouded cockpit quarter windows being replaced with newly manufactured ones. We still have a lot of the glazing to replace but it is getting done bit by bit! The gunners window and the astrodome are going to be a bit more of a headache, but they will get done.

We've had some new flooring going down inside the aircraft, it's not the original (does anybidy know a source of the proper stuff?) but it stops the inside of 963 being so much of a trip hazard than it was. When I say 'Trip hazards' that doesn't include the wing spars... everybody takes their own chances there!

As I mentioned earlier, all leaks and weeps are being investigated, one showstopping item being found in the engines priming lines - a couple of perished gaskets which would have produced a really nasty engine fire had they not been spotted. They have been changed and to get preventative, the same job is being done on the other three engines.

One of the fuel tank cocks on the port side is leaking, so that has been added to the list of tasks we have to sort out before running engines on that side. We have four tanks in each wing feeding into a five way manifold, so it should be fairly straight forward to figure out which one it is. We've already been in behind the engines once to fit new cut off solenoids on the priming lines, and fuel pressure senders, so we can be more accurate with priming and reduce the risk of fire.

Some other leaks are going to be more fun to sort out - a bomb bay ram has started weeping slightly which is going to need attention, but we're not sure if it's just misbehaving due to lack of use. The system is holding pressure well, the bomb doors being hand pumped shut the week before the hangar time, and so far the only thing that has happened is the port door has crept open a couple of inches.

The undercarraige oleo legs were to have been inflated but it appears we may have a leaks on the oleo legs themselves. This means an undercarraige leg swap if we can't get it fixed in situ.

None of this work worries us, for two reasons. We have a can-do attitude to the aircraft and if we can't find a way to do something we will find someone who can help... which is why we've been bugging anybody in the UK that has built Shackleton propellers recently!

The other reason is that in a small room off the hangar is every drawing that exists for the Shackleton, all the mod details, and God knows what else. It's a treasure trove. Apparently we hold the design rights to the aircraft now, having all the master copies of the drawings and prints. There is a phenomenal amount of information in there.

But, with all problems that crop up, she's an old aeroplane so we can forgive her.

What of the coming season, and the future?

So far this year we're looking at running on the 22nd for the opening of Airbase 2011 season, or the 4th May for the press day, or both.. the team is that enthusiastic. Further runs are planned for later in the year, and I'll put them up on here as they are known.

This year marks 20 years in retirement for the Shackleton, with 963's last flight being on 09.07.1991, after 15483.45 hours. We hope to mark it in some way.

As for the future...well, we're looking at new ways to get some big amounts of funding in place to get WR963 indoors. After that anything could happen.

Kind regards,

Rich Woods

Shackleton Preservation Trust

Well, we finally got lucky with the old Shackleton, being given some hangar time to get the painting done (more of which later) thanks to the kindness of Classic Flight at Coventry. They moved several of their collection out into the cold for a few nights including this funny looking US built thing:

Howard 500 N500LN...

Anyway... back to things with the proper number and arrangement of engines.

Wall to wall sunshine over the past few weeks let us make progress on the prep work for the paint, and not a moment too soon. All the team have been working from dawn to dusk every day they can - with some of the guys going to the airport in the evenings, going away from the aircraft exhausted but happy.

963 was made ready for moving (she has to shuffle over a bit soon anyway to make room for DC-6 G-SIXC to get past into its new position) the dates for the hangar being set at 24 - 27 March. We were to have a a four day paintathon, the intention being to only have roundels and stencils left to do afterward.

I thought I was prepared for it... I really wasn't. From the first e-mails last night saying 963 was in the hangar a day early, everything went nuts. I loaded up the car with as much painting materials as I could the following morning and set off for Coventry, eager to see what was going on there. I couldn't believe how busy the place was... it seemed as if everything was being worked on at once. Classic Flight/Airbase's second season is going to be a cracker.

The paintathon..

Arriving to find everything sunny and bright I made my way over to where the Shackleton now wasn't, to drop the paint supplies off. I'm sure this was where we left it?

Best go look inside then. There she is!! Asking around the place and a figure of 17 years was arrived at since she last saw the inside of a hangar.

Two of our guys were already hard at work starting to mask up the windows and cover the floor, as was requested of us. The team are all in good spirits, even when asked to unroll the plastic floor covering again (and again) for the camera..

The ground handlers were superb, putting 963 in the hangar bang on the centre line with barely feet to spare on the wingtips. This is how close it was:

As you can see it's a snug fit.

Helping out with the masking, I had to take this shot, as it was too good to miss:

The DC3 was started up later in the afternoon outside, and made a really very pleasing amount of noise. :diablo:

Being at the west end of the hangar meant we got the sunshine for longer, which was rather nice. 963 looked that happy in there it was rather tempting to let the tires down so we don't have to move out, squat in the aircraft, or just paint a line on the floor that's Shackleton shaped with a "reserved" sign on it...

Saturday we worked long into the night, pausing only briefly for food and once in shock, when one of the female members of our painting team dropped into conversation that she was a pole dancing instructor...

Unfortunately we got beaten by time, WR963 wasn't finished. Various small leaks caused problems with contaminating paint.Then the paint we had for the roundels/fin flashes started reacting, so they were redone the following week. Luckily we noticed it after the first fin flash, so we didn't have to worry about any large areas. We overestimated the need for some colours, and underestimated others, but on the whole she's about 90% done.

These last two were taken right before we left.

WR963 was pushed out on 30th March, after 7 days indoors, and some of our gang were down there to see it happen. Still a bit more to do, but this picture was too good not to miss.

Two weeks later and other than the long standing issue of No 2's propeller, she looks smashing. I'm not going to post pictures for now, as we've decided to try and roll out the finished article for Airbase first day of business this year, so we promised to hold any photo's until then..

963 now wears the national markings, her squadron codes and emblems. The stenciling is getting done, and we'll have the most noticeable bits done by the time the public see her for the first time. Walkways, drain points, emergency markings... even in plain white and grey a Shackleton is a colourful beast up close.

The only pain with the paint is the underwings - despite best efforts, it's still slow going under there, so she won't be wearing the underwing serial numbers for a couple of weeks yet. The biggest reason being while we stopped things leaking into 963, there's still a few leaks out. We'll get to the bottom of them though.

In terms of crew numbers, we had around 20 people working on the Shackleton over the painting weekend, which is kind of a record for us. Even the elder members of the group can't remember seeing that many people working on her in the 12 years that she has been in their care. It's all good as the average on a normal day now is between 10 and 15 members, making large tasks that much easier. The ever growing "list" is now being fought to a standstill, and within a short time it's going to start getting smaller.

We've had two of the badly clouded cockpit quarter windows being replaced with newly manufactured ones. We still have a lot of the glazing to replace but it is getting done bit by bit! The gunners window and the astrodome are going to be a bit more of a headache, but they will get done.

We've had some new flooring going down inside the aircraft, it's not the original (does anybidy know a source of the proper stuff?) but it stops the inside of 963 being so much of a trip hazard than it was. When I say 'Trip hazards' that doesn't include the wing spars... everybody takes their own chances there!

As I mentioned earlier, all leaks and weeps are being investigated, one showstopping item being found in the engines priming lines - a couple of perished gaskets which would have produced a really nasty engine fire had they not been spotted. They have been changed and to get preventative, the same job is being done on the other three engines.

One of the fuel tank cocks on the port side is leaking, so that has been added to the list of tasks we have to sort out before running engines on that side. We have four tanks in each wing feeding into a five way manifold, so it should be fairly straight forward to figure out which one it is. We've already been in behind the engines once to fit new cut off solenoids on the priming lines, and fuel pressure senders, so we can be more accurate with priming and reduce the risk of fire.

Some other leaks are going to be more fun to sort out - a bomb bay ram has started weeping slightly which is going to need attention, but we're not sure if it's just misbehaving due to lack of use. The system is holding pressure well, the bomb doors being hand pumped shut the week before the hangar time, and so far the only thing that has happened is the port door has crept open a couple of inches.

The undercarraige oleo legs were to have been inflated but it appears we may have a leaks on the oleo legs themselves. This means an undercarraige leg swap if we can't get it fixed in situ.

None of this work worries us, for two reasons. We have a can-do attitude to the aircraft and if we can't find a way to do something we will find someone who can help... which is why we've been bugging anybody in the UK that has built Shackleton propellers recently!

The other reason is that in a small room off the hangar is every drawing that exists for the Shackleton, all the mod details, and God knows what else. It's a treasure trove. Apparently we hold the design rights to the aircraft now, having all the master copies of the drawings and prints. There is a phenomenal amount of information in there.

But, with all problems that crop up, she's an old aeroplane so we can forgive her.

What of the coming season, and the future?

So far this year we're looking at running on the 22nd for the opening of Airbase 2011 season, or the 4th May for the press day, or both.. the team is that enthusiastic. Further runs are planned for later in the year, and I'll put them up on here as they are known.

This year marks 20 years in retirement for the Shackleton, with 963's last flight being on 09.07.1991, after 15483.45 hours. We hope to mark it in some way.

As for the future...well, we're looking at new ways to get some big amounts of funding in place to get WR963 indoors. After that anything could happen.

Kind regards,

Rich Woods

Shackleton Preservation Trust

Re: Avro Shackleton WR963

Mon Apr 11, 2011 11:11 am

Great update, keep up the good work.

Re: Avro Shackleton WR963

Mon Apr 11, 2011 11:59 am

Great pics and great progress, congrats.

Sounds like just the right person for ...

And we are speaking of the person in pic #11 I presume.

August

Richard Woods wrote:Saturday we worked long into the night, pausing only briefly for food and once in shock, when one of the female members of our painting team dropped into conversation that she was a pole dancing instructor...

Sounds like just the right person for ...

The undercarraige oleo legs were to have been inflated but it appears we may have a leaks on the oleo legs themselves. This means an undercarraige leg swap if we can't get it fixed in situ.

And we are speaking of the person in pic #11 I presume.

August

Re: Avro Shackleton WR963

Tue Apr 26, 2011 6:01 am

Hi all,

More updates from us regarding the old Shackleton...

I've been asked to point out that while she is flattered by the comment, the young lady in my picture isn't the pole dancing instructor. Sorry!

16 April

Today was our practice day for the opening, and the first chance to show our hard work off. Our support group the "Friends of WR963". The Coastal Command scheme hasn't been seen on a Shackleton since 1957, and in the sunlight looks absolutely fantastic - it really transforms the aircraft.

WR963 behaved herself well for the small crowd, which included a few Shackleton Association members, friends, family, and ex Shackleton aircrew. She still threw up some snags though, to keep us busy this coming week.

The guys set to with pre-oiling, running the props through for 4 minutes with the oilers on. After clearance from the tower and with the fire crew in place, 13.00hrs saw No 3 engine cough into life. No 4 and No 1 were asked to join in shortly afterwards. No 1 not having been run in 18 months was a little reluctant but caught and ran on the second attempt.

No 3 engine (the one with the bad cams), seemed a little poorly.... and I'm hoping it makes it to the end of the season. It started almost instantly, and came on the throttle with a minimal amount of priming, but as it went up to 30" boost it began misfiring and misbehaving. Oil pressure was slightly on the low side, it was running hotter than normal, and to add insult it suffered a mag drop too. We'll fettle it as best we can, but it's looking ever more likely that we have another engine change to do.

The hydraulics were exercised, and the worrying leak on the starboard rear bomb bay ram seems to have stopped. We can only put to slight shrinkage in one of the seals due to inactivity, but we're keeping an eye on it and the first time it show fluid again, we'll swap the ram.

The intercom also had it's own problem, with some very annoying feedback from certain positions in the aircraft making crew communication difficult at times.

Snags are to be expected on an aeroplane her age though, and summer makes it easier to deal with.

Several of us are doing midweek work (days and evenings) to try and finish off the stencils, and cure the issues thrown up this Saturday, in time for the 22nd. The main reason being 22nd is a big day for our old Shackleton.... the first public appearance in her new colours and her first public run this year in support of Airbase's re-opening.

22 April - Rollout day

We left Coventry on Wednesday night (20th April) after a day spent working on the props. We had to rectify a damaged blade tip, which was showing signs of corroson - which then meant fettling the other two blades on that unit to match. The work was all done as listed in the prop manuals and I hope I never have to polish one to a mirror finish, by hand, ever again!

No 2 engine should hopefully have props on it by the 4th May, then we'll de-inhibit it and see how it runs. Lots of people were trying hard to get the props built for today, (we had a good few phonecalls earlier this week about it) but time was against us once everything got sorted out. All the blades, hubs, and manuals are in Airbase's hangar in one place waiting for whoever has been tasked to build them.

The last problem remaining for the big day was the Shackleton was still outside. We were more than a bit worried on arriving this morning to find her still outside - the reason being she wouldn't fit through the hangar doors. The doors have a stop on them at the Airbase end which means 963 has a wingspan about 10 ft too much to get in. At the other end she fits great, but it is airside, which means there is no public access and unsuitable for a roll out.

So, the tug was attached and with the usual high level of skill the ground staff moved 963 as far in as she could go.

She stayed there for an hour or so, while there was the roll out ceremony with the Mayor of Coventry, and various news crews, before they were invited for lunch in the DC6 diner (formerly G-SIXC, nicely converted internally to a 50's style.)

While they were getting some food inside them, the other DC6 (G-APSA) was pushed back to make room for 963 to take up her own spot beside the Nimrod. We than started the necessary checks, and erected a small fence to stop the public getting too close to 18 fast moving prop blades.

Engine start time drew closer, and I was getting more nervous by the second. I had the task of waking 963 today, being the engineer for the run, overseen by our regular engineer and excellent teacher, Gerry Broad. Youtube shows (on this aircraft) what happens if you get it wrong, and this was my first time in the engineer's seat after training..

With the Mayor and several others on board I was praying for her not to throw a tantrum like last Saturday. The big old bomber must have been listening as she performed flawlessly, with no intercom problems this time, and no misfiring or shenanigans from No 3 engine. It caught and ran well from the moment the switches were pushed, as did the others.

(photo borrowed from a guest of ours.)

We all took a deep sigh of relief after the shutdown, and the silence was broken by applause... so I guess the crowd liked it. We have it all to do again on the 4th May for Airbase's Press Day though, so if you didn't catch it this time around there's still chance if you're in Coventry on that date.

Big thanks goes to the guys at Airbase, for letting us do the roll out on the first day of their opening, and being so eager to support us. Video of the event was taken, and we made national news and a couple of the local papers.

http://www.youtube.com/watch?v=NDBT1uHsexU

Kind regards,

Rich

More updates from us regarding the old Shackleton...

I've been asked to point out that while she is flattered by the comment, the young lady in my picture isn't the pole dancing instructor. Sorry!

16 April

Today was our practice day for the opening, and the first chance to show our hard work off. Our support group the "Friends of WR963". The Coastal Command scheme hasn't been seen on a Shackleton since 1957, and in the sunlight looks absolutely fantastic - it really transforms the aircraft.

WR963 behaved herself well for the small crowd, which included a few Shackleton Association members, friends, family, and ex Shackleton aircrew. She still threw up some snags though, to keep us busy this coming week.

The guys set to with pre-oiling, running the props through for 4 minutes with the oilers on. After clearance from the tower and with the fire crew in place, 13.00hrs saw No 3 engine cough into life. No 4 and No 1 were asked to join in shortly afterwards. No 1 not having been run in 18 months was a little reluctant but caught and ran on the second attempt.

No 3 engine (the one with the bad cams), seemed a little poorly.... and I'm hoping it makes it to the end of the season. It started almost instantly, and came on the throttle with a minimal amount of priming, but as it went up to 30" boost it began misfiring and misbehaving. Oil pressure was slightly on the low side, it was running hotter than normal, and to add insult it suffered a mag drop too. We'll fettle it as best we can, but it's looking ever more likely that we have another engine change to do.

The hydraulics were exercised, and the worrying leak on the starboard rear bomb bay ram seems to have stopped. We can only put to slight shrinkage in one of the seals due to inactivity, but we're keeping an eye on it and the first time it show fluid again, we'll swap the ram.

The intercom also had it's own problem, with some very annoying feedback from certain positions in the aircraft making crew communication difficult at times.

Snags are to be expected on an aeroplane her age though, and summer makes it easier to deal with.

Several of us are doing midweek work (days and evenings) to try and finish off the stencils, and cure the issues thrown up this Saturday, in time for the 22nd. The main reason being 22nd is a big day for our old Shackleton.... the first public appearance in her new colours and her first public run this year in support of Airbase's re-opening.

22 April - Rollout day

We left Coventry on Wednesday night (20th April) after a day spent working on the props. We had to rectify a damaged blade tip, which was showing signs of corroson - which then meant fettling the other two blades on that unit to match. The work was all done as listed in the prop manuals and I hope I never have to polish one to a mirror finish, by hand, ever again!

No 2 engine should hopefully have props on it by the 4th May, then we'll de-inhibit it and see how it runs. Lots of people were trying hard to get the props built for today, (we had a good few phonecalls earlier this week about it) but time was against us once everything got sorted out. All the blades, hubs, and manuals are in Airbase's hangar in one place waiting for whoever has been tasked to build them.

The last problem remaining for the big day was the Shackleton was still outside. We were more than a bit worried on arriving this morning to find her still outside - the reason being she wouldn't fit through the hangar doors. The doors have a stop on them at the Airbase end which means 963 has a wingspan about 10 ft too much to get in. At the other end she fits great, but it is airside, which means there is no public access and unsuitable for a roll out.

So, the tug was attached and with the usual high level of skill the ground staff moved 963 as far in as she could go.

She stayed there for an hour or so, while there was the roll out ceremony with the Mayor of Coventry, and various news crews, before they were invited for lunch in the DC6 diner (formerly G-SIXC, nicely converted internally to a 50's style.)

While they were getting some food inside them, the other DC6 (G-APSA) was pushed back to make room for 963 to take up her own spot beside the Nimrod. We than started the necessary checks, and erected a small fence to stop the public getting too close to 18 fast moving prop blades.

Engine start time drew closer, and I was getting more nervous by the second. I had the task of waking 963 today, being the engineer for the run, overseen by our regular engineer and excellent teacher, Gerry Broad. Youtube shows (on this aircraft) what happens if you get it wrong, and this was my first time in the engineer's seat after training..

With the Mayor and several others on board I was praying for her not to throw a tantrum like last Saturday. The big old bomber must have been listening as she performed flawlessly, with no intercom problems this time, and no misfiring or shenanigans from No 3 engine. It caught and ran well from the moment the switches were pushed, as did the others.

(photo borrowed from a guest of ours.)

We all took a deep sigh of relief after the shutdown, and the silence was broken by applause... so I guess the crowd liked it. We have it all to do again on the 4th May for Airbase's Press Day though, so if you didn't catch it this time around there's still chance if you're in Coventry on that date.

Big thanks goes to the guys at Airbase, for letting us do the roll out on the first day of their opening, and being so eager to support us. Video of the event was taken, and we made national news and a couple of the local papers.

http://www.youtube.com/watch?v=NDBT1uHsexU

Kind regards,

Rich

Re: Avro Shackleton WR963

Fri May 20, 2011 4:33 am

Time for some more updates!

4th May

The Press Day at Coventry on looked to be well attended with people wandering around from various publications and organisations. Hopefully a sign of things to come as there has been a LOT of hard work done at Coventry on things other than the Shackleton by a lot of people. It's cool to watch the place evolve.

Crew for the run on the Press Day was:

Dave Woods and Ricky Marriott in Pilot and Co-pilot positions, myself as Engineer, and John Cubberley overseeing us. We also were also thrilled to have aboard Don Johnson as a guest. Don was an Auster pilot in the Malaysian jungle during WW2 and had no end of stories to tell.

WR963 once again behaved herself with only a couple of problems. We had an intercom issue which caused a bit of feedback until it was traced, and a weeping fuel priming line.

As it was late in the day we had to leave it until the next visit.

7th May

A wet Saturday down at Coventry but a reasonable days work. Two of our guys are busy at work cleaning and repainting parts of the interior, a couple of us went leak chasing and the pneumatics should be back before long.

Leaks:

First up... the heavy rain has shown we have some more work to do. The prolonged dry spell has dried out more of the old mastic around the cockpit canopy frame and the beam lookout windows. We have water dribbles! The next fine day will see it sorted as we'll dig all the old stuff out and put new in.

More worrying was the fuel leak. When we shut down we found the priming overflow on the starboard side was still chucking raw fuel out - but with the pump off. Initial thoughts were that I had overprimed during the start, but not so. The supply line into the fuel priming pump was weeping fuel. We got it off the aircraft today and this is the state of it:

It caused a few sharp intakes of breath when we took it off. It must have cracked to the point of failing on this last run. Typically this pipe is hard to see hidden behind the air intake and outlets for the generator, so you could only feel it rather than see it until it was off. I'm not convinced its the original pipe, I think its a legacy from 10 - 15 years ago when Air Atlantique were using her as a test bed.

So, from now until we can get Pirtek to come visit, 963 will be a bit quieter than she has been for the past month! All being well she'll be fit and well by this time next week

The air bottles came back from testing today, with all the NDT, x-ray, ultrasound, and boroscope testing done. Four bottles passed, one bottle failed with the wall thickness down to less than 1.6mm and metal flakes seen on the x-ray! Luckily for us we only need four, but a good job we sent the spare too.

The props are currently across the other side of the airfield causing much head scratching at CFS, as the last ones they did were in the late 1990's for the AEW2 that went to the USA. I should have more news later if all goes well - but we have to admit things have slipped a little with getting this sorted out.

14th May

Windy again at Coventry, but dry!

Plenty to do on 963 though to get her even better and keep her in good condition for the coming season. Vic and Rich Marriott are making immense progress on the interior, I couldn't get photo's due to getting in their way. When I left Coventry at 4.30pm they were still hard at work, somewhere near the galley. Repairs to floor matting and the bunk area were happening last time I looked.

Pirtek when phoned arrived at the airport within the hour (the guy on the phone asking "Is it the old Shackleton again? No problem!") and when we gave them the old pipe we had a nice shiny new one produced inside 10 minutes. The old spec of the pipe isn't available any more so an equivalent was used.

Thinking about it; there's now enough non original parts on this aircraft to give the CAA and anyone else a field day if it had to be audited for flight. But as it's probably not going to happen we can use slightly better materials without getting it approved. Hopefully the work we're doing will keep the Shackleton 'live' for a good many years.

With the new priming line fitted, it was then just a case of switching the internal power on, selecting fuel tanks and master cocks for that side, and turning the priming switch to No 3. The pump hummed away with no nasty noises and no leaks... so 963 is good to run again.

Feeling happy with our success we moved on to what would have been last weeks task - the refitting of the air bottles in the pneumatics crate. Myself and Pete Curran took this job on, and braving spiky little bits of safety wire and stiff air hoses, we had the bottles in fairly quickly.

There was a little bit of head scratching to figure out where all the joints ran to avoid chafing and rubbing.

We than fed the bypass pipes fitted to the oxygen cylinders (as they have been used in the past for extra capacity) back into the crate and gently opened the taps.

Hissing noises were heard and then port and starboard pressure gauges started to climb! There is a small leak off the bottom pair of cylinders, and what little pressure we had bled away fairly quickly, so we'll test the whole system from top to bottom next week. Volunteers were called for and with one man standing next to each wheel, one down in the nose near the crate, and one in the pilots seat; the brakes were pressed. Port brakes took up and then vented nicely, starboard took a little more persuasion, finally coming on with a drawn out creak and then a puff of years old brake dust out the sides! There didn't seem to be any sudden great loss of air, so it appears the brake bags are still intact.

So... 963 now has her brakes back. We need one more propeller and then a mainwheel tyre change, then maybe we can show her the runway again...

The propeller - this is a long standing bugbear, however it is now in the workshop being built up. It appears we're missing an intershaft bearing and seal, so it might take a little while to find those. Other than that everything seems to be okay on that score.

Next we decided to have a crack at removing some of the stiffness from the throttle linkages. Well, that was the excuse. In reality all of us have been itching to get those front doors open and see what state she is in, in one of the places we haven't been for a while. Well we weren't disappointed.. in there we found graffiti from the radar fit, original 50's paint, a couple of birds nests and a lot of work!

You never realise just how big that bomb bay is until all the doors are open, the AEW uses roughly two thirds of it and it seems cavernous at that. We're still planning around the possibility of re-instating the full length doors. There is MUCH more left over from the MR2 than anybody would think, and the position of where the doors were cut makes it look to be a job that can be done over Autumn/Winter. We've promised Airbase that we won't start taking big chunks of Shackleton apart until after show season!

Regards,

Rich

4th May

The Press Day at Coventry on looked to be well attended with people wandering around from various publications and organisations. Hopefully a sign of things to come as there has been a LOT of hard work done at Coventry on things other than the Shackleton by a lot of people. It's cool to watch the place evolve.

Crew for the run on the Press Day was:

Dave Woods and Ricky Marriott in Pilot and Co-pilot positions, myself as Engineer, and John Cubberley overseeing us. We also were also thrilled to have aboard Don Johnson as a guest. Don was an Auster pilot in the Malaysian jungle during WW2 and had no end of stories to tell.

WR963 once again behaved herself with only a couple of problems. We had an intercom issue which caused a bit of feedback until it was traced, and a weeping fuel priming line.

As it was late in the day we had to leave it until the next visit.

7th May

A wet Saturday down at Coventry but a reasonable days work. Two of our guys are busy at work cleaning and repainting parts of the interior, a couple of us went leak chasing and the pneumatics should be back before long.

Leaks:

First up... the heavy rain has shown we have some more work to do. The prolonged dry spell has dried out more of the old mastic around the cockpit canopy frame and the beam lookout windows. We have water dribbles! The next fine day will see it sorted as we'll dig all the old stuff out and put new in.

More worrying was the fuel leak. When we shut down we found the priming overflow on the starboard side was still chucking raw fuel out - but with the pump off. Initial thoughts were that I had overprimed during the start, but not so. The supply line into the fuel priming pump was weeping fuel. We got it off the aircraft today and this is the state of it:

It caused a few sharp intakes of breath when we took it off. It must have cracked to the point of failing on this last run. Typically this pipe is hard to see hidden behind the air intake and outlets for the generator, so you could only feel it rather than see it until it was off. I'm not convinced its the original pipe, I think its a legacy from 10 - 15 years ago when Air Atlantique were using her as a test bed.

So, from now until we can get Pirtek to come visit, 963 will be a bit quieter than she has been for the past month! All being well she'll be fit and well by this time next week

The air bottles came back from testing today, with all the NDT, x-ray, ultrasound, and boroscope testing done. Four bottles passed, one bottle failed with the wall thickness down to less than 1.6mm and metal flakes seen on the x-ray! Luckily for us we only need four, but a good job we sent the spare too.

The props are currently across the other side of the airfield causing much head scratching at CFS, as the last ones they did were in the late 1990's for the AEW2 that went to the USA. I should have more news later if all goes well - but we have to admit things have slipped a little with getting this sorted out.

14th May

Windy again at Coventry, but dry!

Plenty to do on 963 though to get her even better and keep her in good condition for the coming season. Vic and Rich Marriott are making immense progress on the interior, I couldn't get photo's due to getting in their way. When I left Coventry at 4.30pm they were still hard at work, somewhere near the galley. Repairs to floor matting and the bunk area were happening last time I looked.

Pirtek when phoned arrived at the airport within the hour (the guy on the phone asking "Is it the old Shackleton again? No problem!") and when we gave them the old pipe we had a nice shiny new one produced inside 10 minutes. The old spec of the pipe isn't available any more so an equivalent was used.

Thinking about it; there's now enough non original parts on this aircraft to give the CAA and anyone else a field day if it had to be audited for flight. But as it's probably not going to happen we can use slightly better materials without getting it approved. Hopefully the work we're doing will keep the Shackleton 'live' for a good many years.

With the new priming line fitted, it was then just a case of switching the internal power on, selecting fuel tanks and master cocks for that side, and turning the priming switch to No 3. The pump hummed away with no nasty noises and no leaks... so 963 is good to run again.

Feeling happy with our success we moved on to what would have been last weeks task - the refitting of the air bottles in the pneumatics crate. Myself and Pete Curran took this job on, and braving spiky little bits of safety wire and stiff air hoses, we had the bottles in fairly quickly.

There was a little bit of head scratching to figure out where all the joints ran to avoid chafing and rubbing.

We than fed the bypass pipes fitted to the oxygen cylinders (as they have been used in the past for extra capacity) back into the crate and gently opened the taps.

Hissing noises were heard and then port and starboard pressure gauges started to climb! There is a small leak off the bottom pair of cylinders, and what little pressure we had bled away fairly quickly, so we'll test the whole system from top to bottom next week. Volunteers were called for and with one man standing next to each wheel, one down in the nose near the crate, and one in the pilots seat; the brakes were pressed. Port brakes took up and then vented nicely, starboard took a little more persuasion, finally coming on with a drawn out creak and then a puff of years old brake dust out the sides! There didn't seem to be any sudden great loss of air, so it appears the brake bags are still intact.

So... 963 now has her brakes back. We need one more propeller and then a mainwheel tyre change, then maybe we can show her the runway again...

The propeller - this is a long standing bugbear, however it is now in the workshop being built up. It appears we're missing an intershaft bearing and seal, so it might take a little while to find those. Other than that everything seems to be okay on that score.

Next we decided to have a crack at removing some of the stiffness from the throttle linkages. Well, that was the excuse. In reality all of us have been itching to get those front doors open and see what state she is in, in one of the places we haven't been for a while. Well we weren't disappointed.. in there we found graffiti from the radar fit, original 50's paint, a couple of birds nests and a lot of work!

You never realise just how big that bomb bay is until all the doors are open, the AEW uses roughly two thirds of it and it seems cavernous at that. We're still planning around the possibility of re-instating the full length doors. There is MUCH more left over from the MR2 than anybody would think, and the position of where the doors were cut makes it look to be a job that can be done over Autumn/Winter. We've promised Airbase that we won't start taking big chunks of Shackleton apart until after show season!

Regards,

Rich