Mon Jun 01, 2009 5:43 am

A2C: Yeah, it's my opinion, but with about 30 years of working on and restoring warbirds as well as 20 years of building, modifying, maintaining and testing frontline combat aircraft as a primary job, I would say that I have a pretty good grasp of the task required. I didn't get far enough in my engineering degree to be able to do the design and stress analysis by the numbers, but can eyeball engineer things pretty close.

Also helps in that I have worked on a couple of BT's over the years and have been studying the -66 prints off and on for a number of years. Were you to have Nelson or Dennis to take this on in their shops full time, you would still be looking at several thousand manhours to do the conversion.

If you want a good idea into the amount of time and thought it takes to do a major conversion, ask Dennis how much time it took him and has dad to work out the first 3350 conversion on a Seafury. Talk with Gary about the time they spent in working up on paper the engine conversion for Fifi..

I'm not trying to burst anyone's bubble about doing it, but rather trying to get them to look at the project with an understanding of the true scope of work required and point at what might be a better way to make things happen. I'm not going to stop anyone from trying it, but in this type of work, sometimes it's more enjoyable to not reinvent the wheel and get out and go play

Also helps in that I have worked on a couple of BT's over the years and have been studying the -66 prints off and on for a number of years. Were you to have Nelson or Dennis to take this on in their shops full time, you would still be looking at several thousand manhours to do the conversion.

If you want a good idea into the amount of time and thought it takes to do a major conversion, ask Dennis how much time it took him and has dad to work out the first 3350 conversion on a Seafury. Talk with Gary about the time they spent in working up on paper the engine conversion for Fifi..

I'm not trying to burst anyone's bubble about doing it, but rather trying to get them to look at the project with an understanding of the true scope of work required and point at what might be a better way to make things happen. I'm not going to stop anyone from trying it, but in this type of work, sometimes it's more enjoyable to not reinvent the wheel and get out and go play

Mon Jun 01, 2009 6:31 am

To follow on from Cvairwerks' point, you are either going to start with a BT or start from scratch with existing aircraft parts (possibly BT). Either way, you are going to need to undertake a stress calculation exercise at al, and effectively arriving at he same (replica with other parts) point from opposite directions - but not easy or, I suspect, cheap. It will be like building a new type - ducking the engine power / stress issues (a low power 'sportlike' version) would be another option - but would still be a 'new aircraft' design. Other alternatives would only be to build an accurate replica, or the only easy one I can think of, take a BT, make it a high-back single seater with pop riveted sheeting and then a P-66 with paint...

Incidentally, I just found this on the Flight Global website while looking for something else:

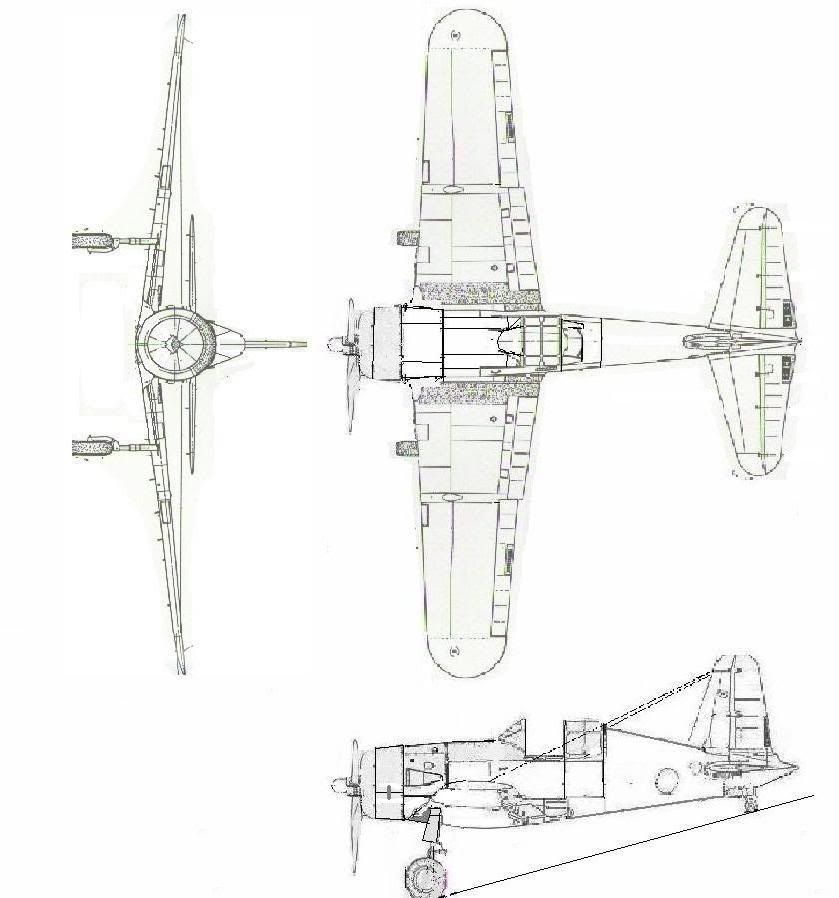

'O'h, that plan view reminds me of something...

Incidentally, I just found this on the Flight Global website while looking for something else:

VULTEE VANGUARD

THE first Vanguards to be received by Great Britain

were a batch of 100 which had been ordered by

Sweden for her rearmament programme, but when

Norway was invaded in the spring of 1940, delivery became

impracticable and the order was transferred to us ; we did

not actually receive the first one, however, until about a

year later, some 50 of the original consignment having in

the meantime been switched to China, whose need of

modern fighter types was even greater than ours—or

greater than most people knew ours to be, at any rate!

Incidentally, Air Marshal "Billy" Bishop, who later

became head of the Royal Canadian Air Force, inspected

the first Vanguard to be handed over to the R.A.F. in

this country.

Even in those comparatively early days of the war,

however, the performance of the Vanguard was hardly up

to the standard of the best British fighters, its top speed

being 350 m.p.h. at 15,100ft;., and its operating speed

299 m.p.h. at 16,oooft. Its service ceiling, however, was

33,000ft., and it had a useful overload range of 1,190 miles,

as compared with a normal range of 700 miles. Its armament

of ten machine guns was very good for the usual

American idea on this department; it was, in fact, one of

the most heavily armed of all American single-seater

fighters. Four of its. guns were mounted in each wing and

the remaining two in the fuselage beneath the decking and

synchronised to fire through the airscrew disc.

The power plant consists of one Pratt and Whitney Twin-

Wasp 14-cylinder air-cooled radial engine, with two-speed

supercharger, developing 1,100 h.p. at 2,250 r.p.m. at

6,200ft., 1,000 h.p. at 2,700 r.p.m. at 14,000ft., and

1,200 h.p. for take-off at 2,700 r.p.m.

All-metal construction with flush-riveted, stressed-skin

covering is employed throughout except for the fabric covered

control surfaces. The fuselage is built in two

sections, the forward section from engine to cockpit being

of welded steel tubing with easily detachable aluminium

panels, and the rear section from cockpit to tail unit being

a semi-monocoque structure. Flaps of the split trailing edge

type are fitted, and the undercarriage, attached well

out on the wide centre-section, retracts inwards ; the tail

wheel is also retractable.

'O'h, that plan view reminds me of something...

Mon Jun 01, 2009 11:28 am

Certainly this should be less of a challenge that designing/building "Mr. Awesome" (3350 on a Yak-11) or "Wildfie" (T-6 with an R-2800)?Cvairwerks wrote:A2C: Yeah, it's my opinion, but with about 30 years of working on and restoring warbirds as well as 20 years of building, modifying, maintaining and testing frontline combat aircraft as a primary job, I would say that I have a pretty good grasp of the task required. I didn't get far enough in my engineering degree to be able to do the design and stress analysis by the numbers, but can eyeball engineer things pretty close.

Mon Jun 01, 2009 2:11 pm

Just have a DER help you decide how to strengthen it.

It looks about the same as building a P-64 from T-6 parts, probably easier, because you wouldn't have to clip the wings.

It looks about the same as building a P-64 from T-6 parts, probably easier, because you wouldn't have to clip the wings.

Mon Jun 01, 2009 4:50 pm

P-66 wing is 37', BT wing is 42'

Mon Jun 01, 2009 5:43 pm

Just saw this thread.

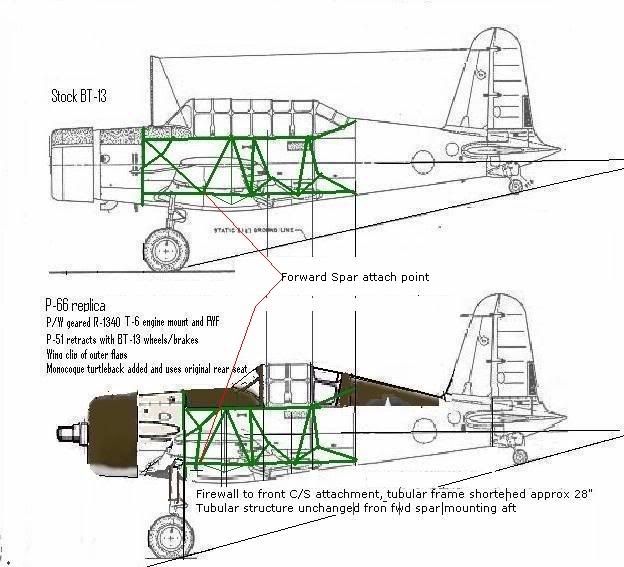

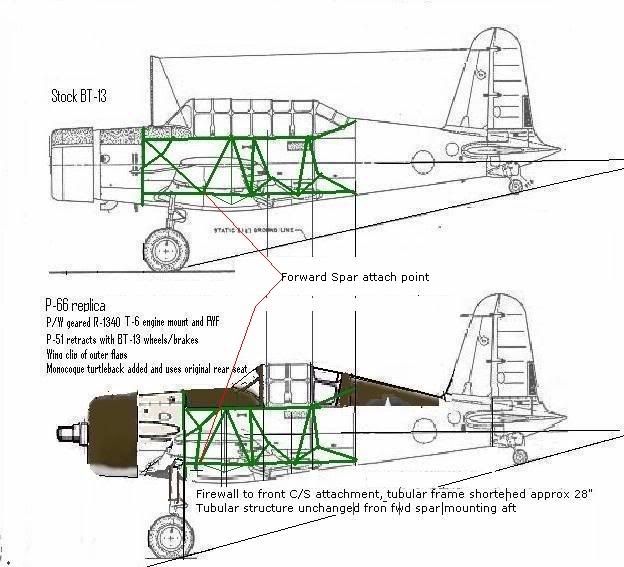

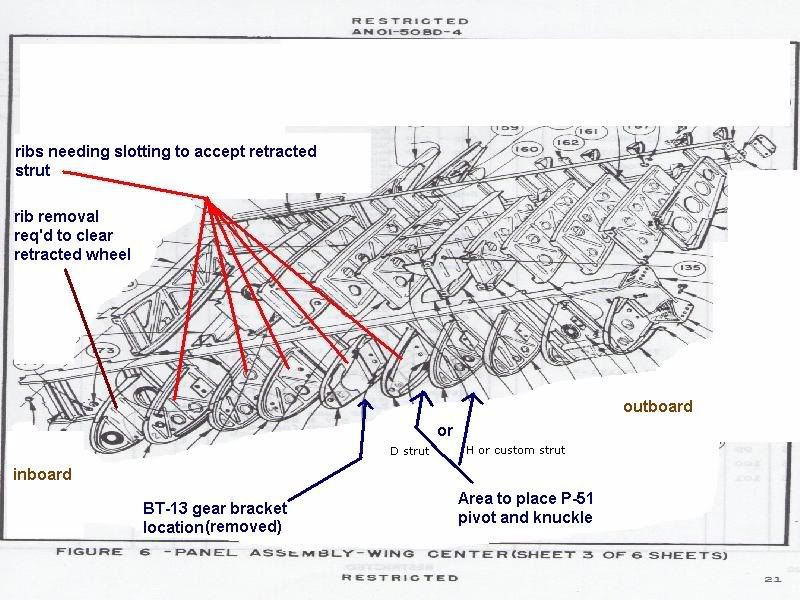

A few years ago I had looked at doing a 'semi-replica' P-66 from a BT-13. Realizing the BT was much lighter built, calculations showed a geared 1340 would give the final product near the same power/wt ratio, and have the same approx diameter cowl. Both planes use the same airfoil. It would also basically use most of a T-6 FWF for parts.

The tube center section of the BT is easily shortened, and the back seat used as the cockpit, being only a few inches off the original, if you did not want to build a new tube center section.

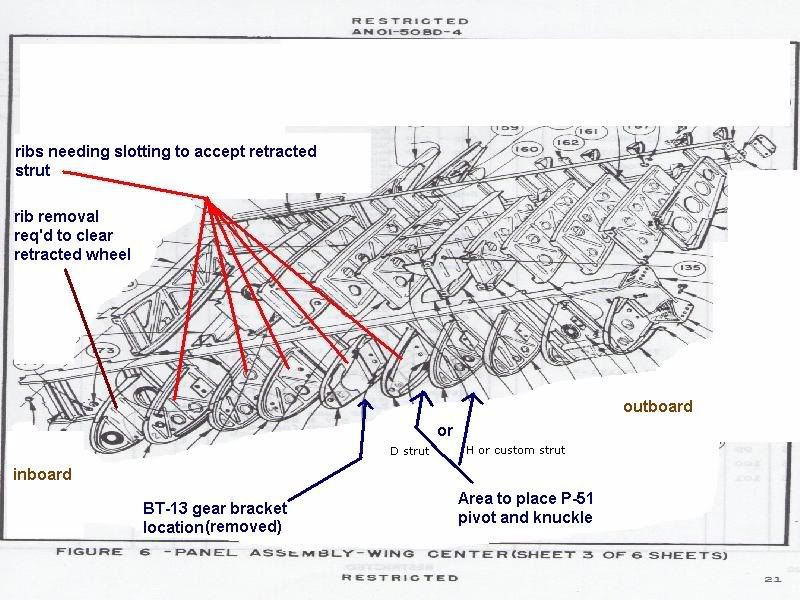

As brought up, adapting retract gear is the major challenge. T-6 gear is too short, but P-51 gear is about perfect if you do not wish to machine your own strut. The wing is shotened by removing the area of the outside flap, and bringing the outer wing inboard.

The weight and balance by rough calculations is actually pretty close, and I have all of the drawings and manuals from the Smithsonian already.

They do need a recheck by an engineer, and again realize this was for a fun replica, not an exact copy.

Here are some of the old initial overview drawings on the conversion I made years ago. I have many many more with details, but hopefully despite the reproduction quality you get the idea.

Hope this is thought provoking.

A few years ago I had looked at doing a 'semi-replica' P-66 from a BT-13. Realizing the BT was much lighter built, calculations showed a geared 1340 would give the final product near the same power/wt ratio, and have the same approx diameter cowl. Both planes use the same airfoil. It would also basically use most of a T-6 FWF for parts.

The tube center section of the BT is easily shortened, and the back seat used as the cockpit, being only a few inches off the original, if you did not want to build a new tube center section.

As brought up, adapting retract gear is the major challenge. T-6 gear is too short, but P-51 gear is about perfect if you do not wish to machine your own strut. The wing is shotened by removing the area of the outside flap, and bringing the outer wing inboard.

The weight and balance by rough calculations is actually pretty close, and I have all of the drawings and manuals from the Smithsonian already.

They do need a recheck by an engineer, and again realize this was for a fun replica, not an exact copy.

Here are some of the old initial overview drawings on the conversion I made years ago. I have many many more with details, but hopefully despite the reproduction quality you get the idea.

Hope this is thought provoking.

Mon Jun 01, 2009 9:12 pm

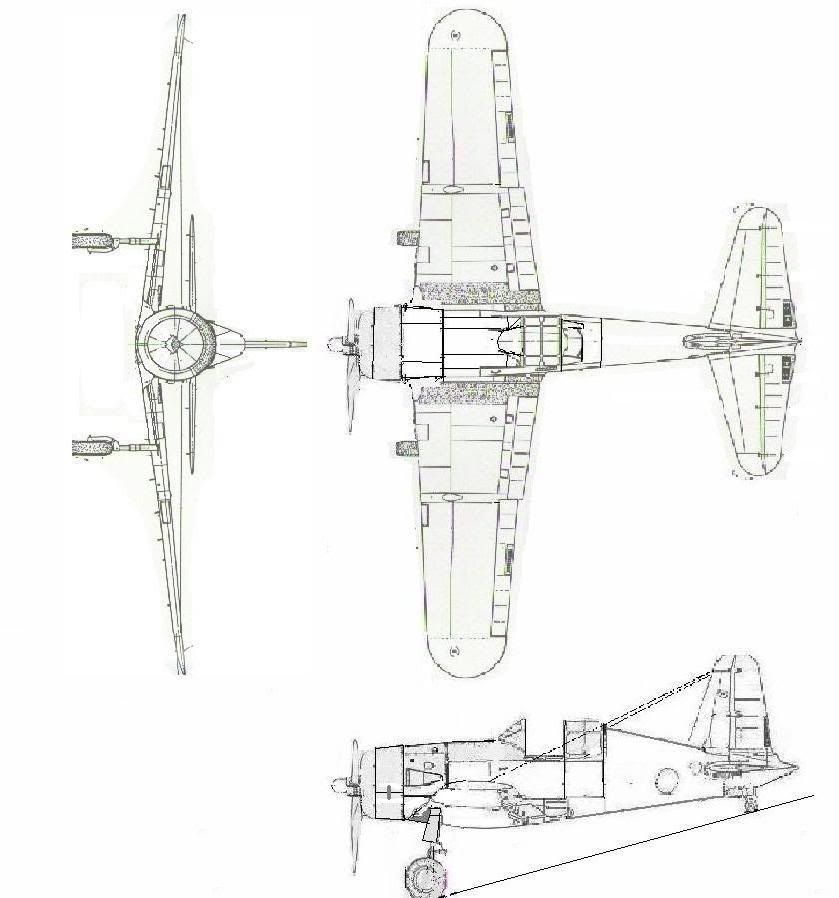

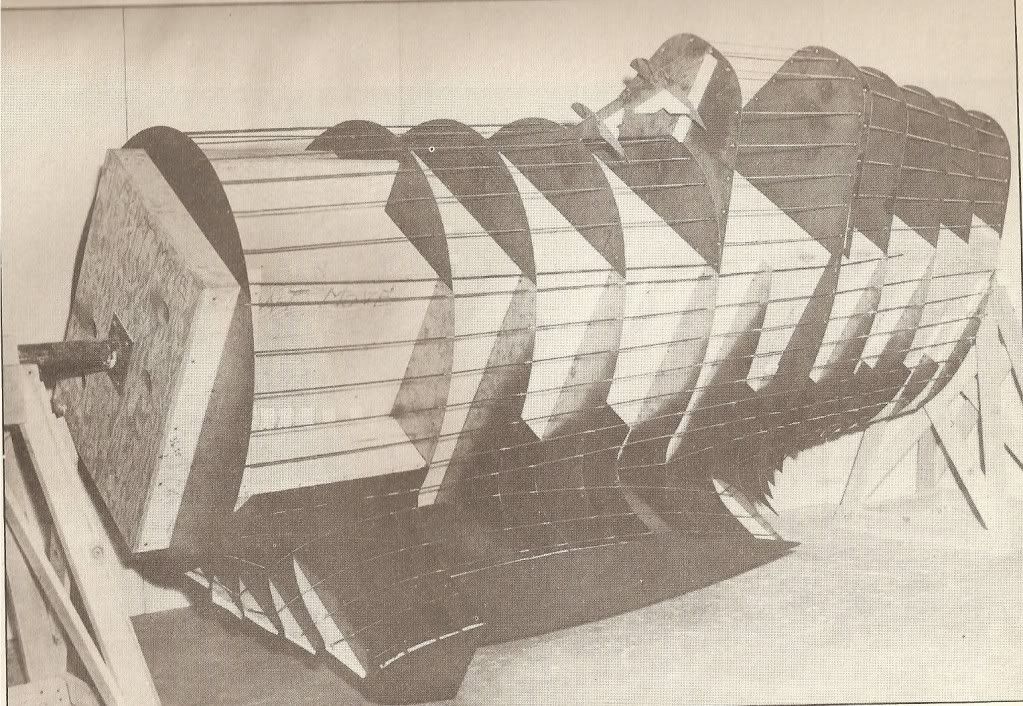

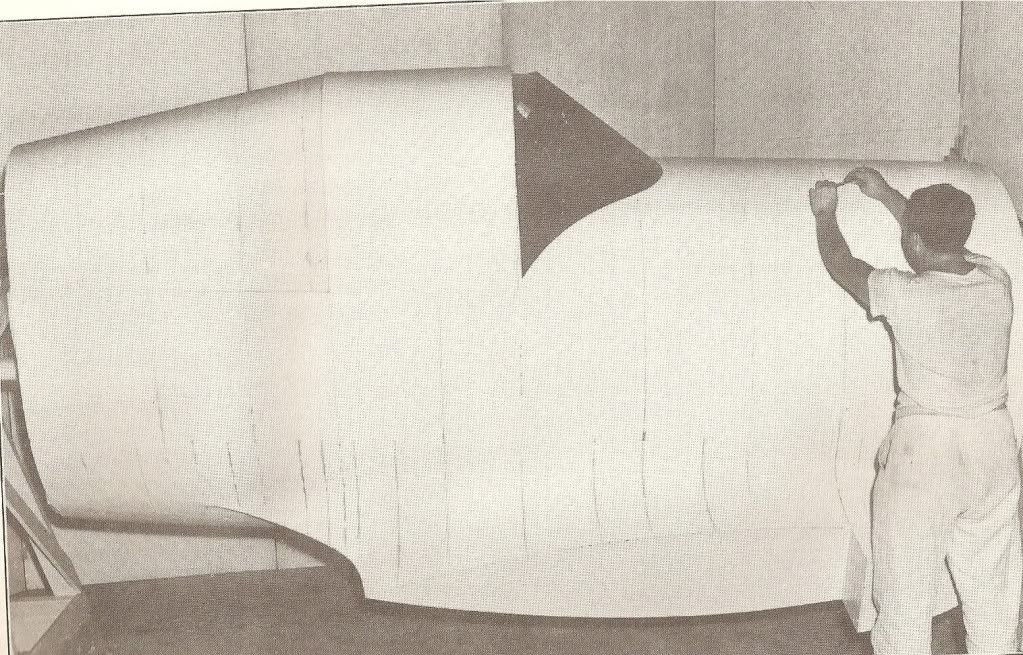

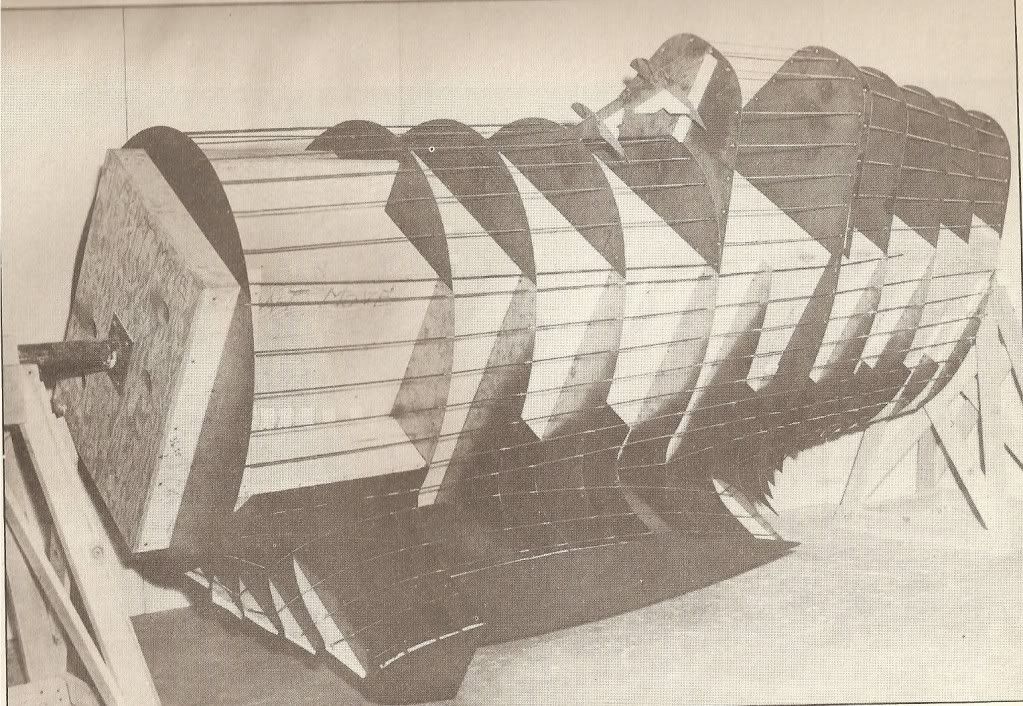

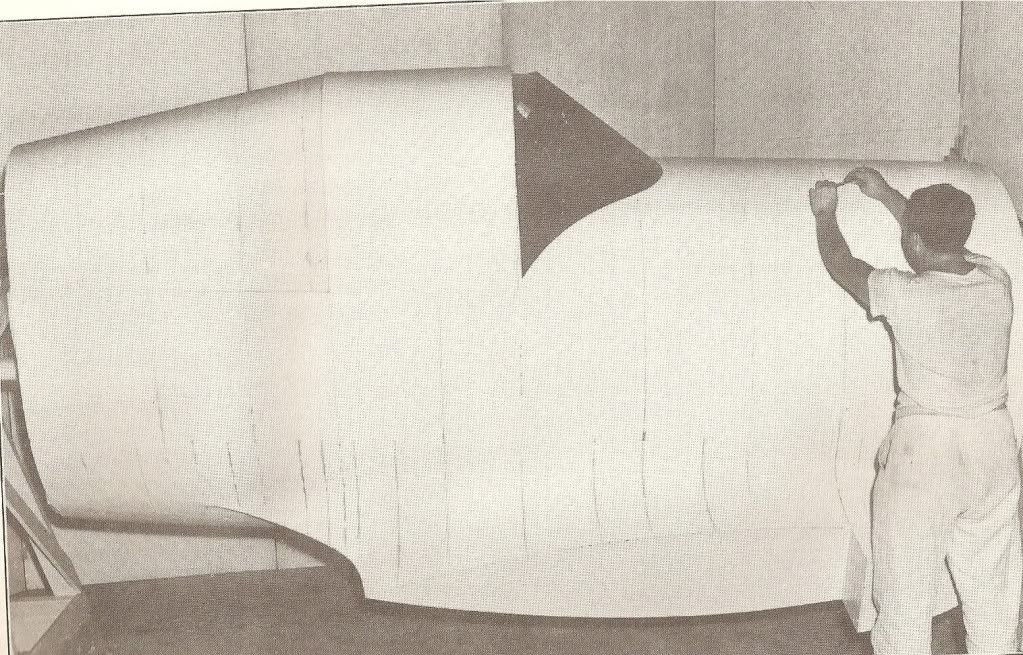

Here are some pics of the P-66 Mockup from a vintage tech manual:

Here are some detail shots of a P-66:

And of a BT-13:

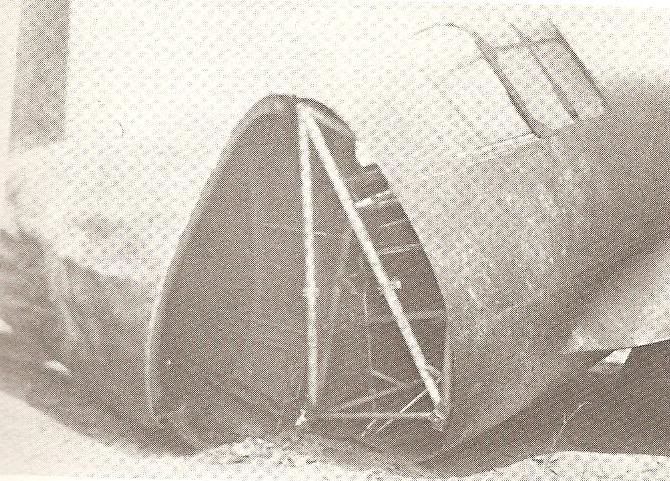

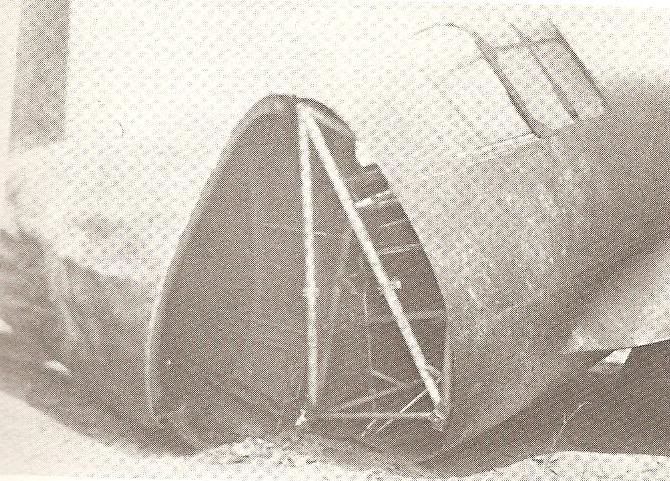

Here is an aft shot of a P-66:

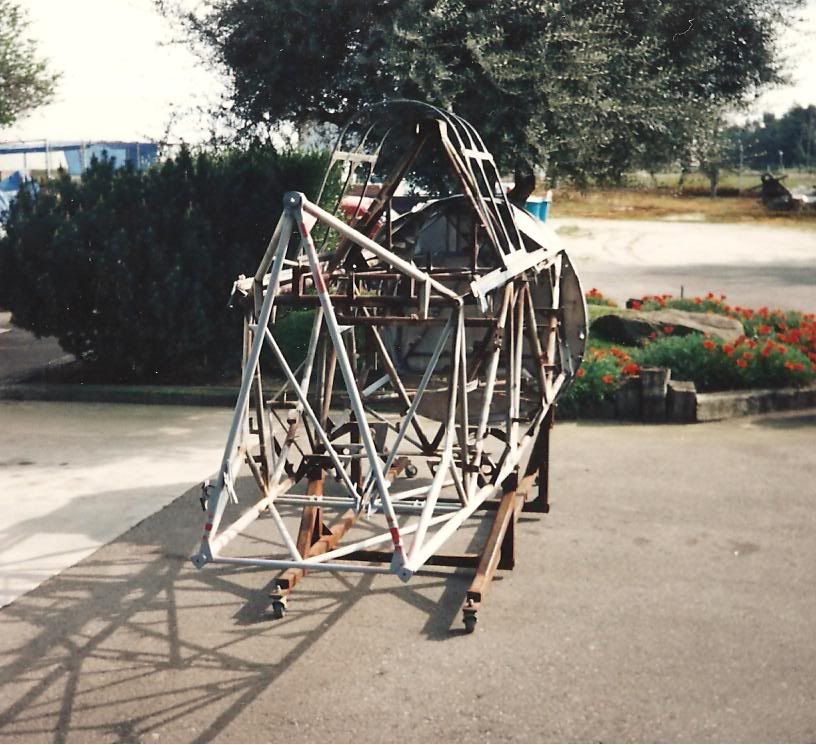

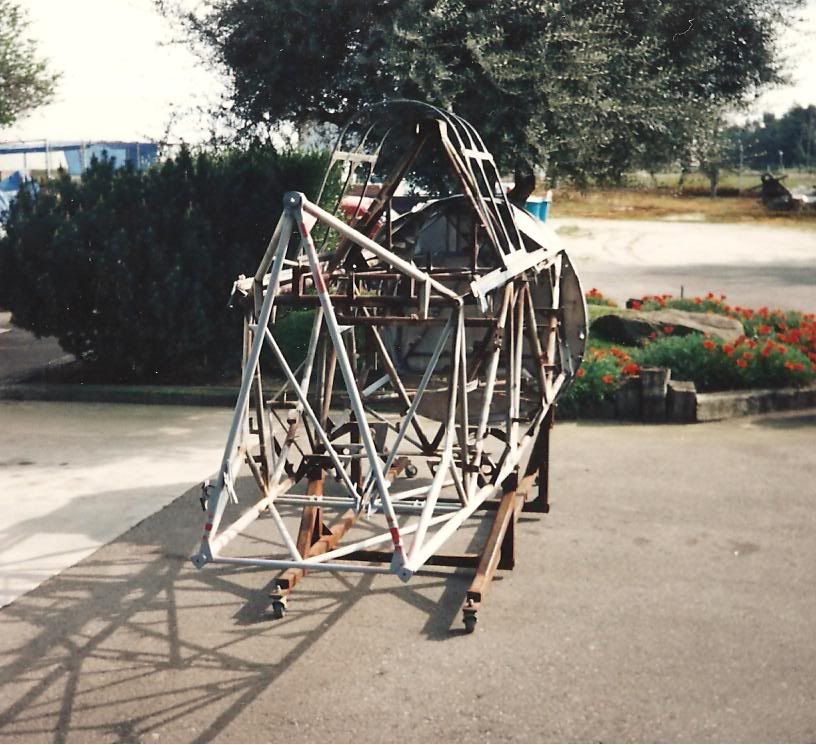

And a BT-13 tubular frame and aft monoque:

Here are some detail shots of a P-66:

And of a BT-13:

Here is an aft shot of a P-66:

And a BT-13 tubular frame and aft monoque:

Mon Jun 01, 2009 9:55 pm

This is shaping up to be one he11 of a cool thread!

Mon Jun 01, 2009 10:50 pm

SNJ5

I have the same drawings, note the rear hood reversed would make the windscrean. I think shortening the wings and moving the ailerons inboard would work. I still think T-6 gear will work if you weld two upper legs together, P-51 legs are 4" to short. Depends on which it cheaper and stronger.

Lay the BT drawings over the P-66 one.

I have the same drawings, note the rear hood reversed would make the windscrean. I think shortening the wings and moving the ailerons inboard would work. I still think T-6 gear will work if you weld two upper legs together, P-51 legs are 4" to short. Depends on which it cheaper and stronger.

Lay the BT drawings over the P-66 one.

Tue Jun 02, 2009 12:49 am

So will this be more accurate to duplicate than a T-6 to a P-64? It appears to be.

Tue Jun 02, 2009 8:55 pm

The T-6 would really be all wrong to duplicate a P-66, I think mostly due to the tail section.

Stoney - another thought on the landing gear I had was to use all T-6 stuff - pivot, retract, locks, gear fork, etc, and just machine two main strut tube housings to accept the t-6 pivot fittings on top and the BT or SNJ piston, fork, scissors and packing on the bottom.

The wet wing is all aft of the spar, so a T-6 pivot does work well.

The P-66 did not have that little outer flap that the BT did, and you can see in my drawing that is what I deleted in the wing cut.

If anyone has any leads on the sighting around Minot, I'm not above going and tracking it down...

Stoney - another thought on the landing gear I had was to use all T-6 stuff - pivot, retract, locks, gear fork, etc, and just machine two main strut tube housings to accept the t-6 pivot fittings on top and the BT or SNJ piston, fork, scissors and packing on the bottom.

The wet wing is all aft of the spar, so a T-6 pivot does work well.

The P-66 did not have that little outer flap that the BT did, and you can see in my drawing that is what I deleted in the wing cut.

If anyone has any leads on the sighting around Minot, I'm not above going and tracking it down...

Tue Jun 02, 2009 8:59 pm

snj5 wrote:The T-6 would really be all wrong to duplicate a P-66, I think mostly due to the tail section.

I think Chris was comparing the T-6 to P-64 'conversion' concept to that of the BT to P-66.

Tue Jun 02, 2009 9:28 pm

JDK wrote:snj5 wrote:The T-6 would really be all wrong to duplicate a P-66, I think mostly due to the tail section.

I think Chris was comparing the T-6 to P-64 'conversion' concept to that of the BT to P-66.

My apologies then and I agree. I think it is a do-able proposition.

Tue Jun 02, 2009 11:43 pm

To do the flaps right, use split flaps like the T-6. I'd make fuel cells and get rid of the wet wing. Make a new tubular and engie mount. I already mentioned flush rivits. Or go to China and find one

A guy can drean.

A guy can drean.

Wed Jun 03, 2009 2:04 am

What about the larger T-6 landing gear supports? How will they fit?