Running with Metal

Fri Sep 30, 2011 7:13 am

Obviously when an engine is making metal there is distress going on and continued operation ought rightly be discouraged. My background is with low horsepower general aviation engines. I know that Lycoming actually has a maximum amount of metal that can be retrieved from the oil filter before an engine must be taken out of service. (One teaspoon IIRC) I have never seen anyone go that length but have known a number of impecunious operators who continue running with metal for a number of hours. I have actually seen the amount found decrease from one inspection to another.

So with the large in lines and radial engines are there similar standards? Is it acceptable, for example on finding metal away from home to fly back to base where there might be the tooling and experience to do the removal? Does it depend on the type of metal found? Bearing material would be more serious compared to piston pin plug material it seems to me. Is there any way to judge how long an engine might run depending on the amount and type of metal found in a screen?

Clearly you don't want to risk losing a pilot and airframe by being too cheap to do a removal away from base but is there an acceptable level of risk in running a high horsepower engine that is "makng metal"?

So with the large in lines and radial engines are there similar standards? Is it acceptable, for example on finding metal away from home to fly back to base where there might be the tooling and experience to do the removal? Does it depend on the type of metal found? Bearing material would be more serious compared to piston pin plug material it seems to me. Is there any way to judge how long an engine might run depending on the amount and type of metal found in a screen?

Clearly you don't want to risk losing a pilot and airframe by being too cheap to do a removal away from base but is there an acceptable level of risk in running a high horsepower engine that is "makng metal"?

Re: Running with Metal

Fri Sep 30, 2011 6:39 pm

Actually it is Continental that allows a limited amount of metal. Airplane should have oil filter kit installed, maybe a chip light, and be on oil analysis that shows metal trends in oil and pinpoints what is making the metal. That is the only way I would operate ANY engine making even a little metal.

IMHO operating with the old style screen filters is just asking for trouble since the metal can go through the screens and cause havoc in the lower engine.

Just a thought.

IMHO operating with the old style screen filters is just asking for trouble since the metal can go through the screens and cause havoc in the lower engine.

Just a thought.

Re: Running with Metal

Fri Sep 30, 2011 6:44 pm

Reading your post again it seems you are asking about ferrying an airplane back to home base. At a minimum to ensure peace of mind I would drain the existing oil and replace, and replace oil filter to ferry back home. A sharp eye should be kept on oil temps and pressures obviously.

Re: Running with Metal

Fri Sep 30, 2011 7:18 pm

Two related stories.

First,

I removed a screen from a Malibu, found a chunk of piston ring with 3 digits of a part number.

Second,

I removed a magnetic drain plug from the sump of a 421, found a roller from the starter drive on it.

The owner had the bushings installed, the shop dropped a roller during removal, stuck in the magnetic plug, told him to fly it.

First,

I removed a screen from a Malibu, found a chunk of piston ring with 3 digits of a part number.

Second,

I removed a magnetic drain plug from the sump of a 421, found a roller from the starter drive on it.

The owner had the bushings installed, the shop dropped a roller during removal, stuck in the magnetic plug, told him to fly it.

Re: Running with Metal

Fri Sep 30, 2011 8:16 pm

Howdy John,

Once upon a time I had the pleasure to do some pilot/mechanic work for an operator of a twin R-2800 powered aircraft during one summer. He had been getting small amounts of metal out of the left engine, it was mainly silver with copper on the back which is main bearing, master rod bearing, etc. on a pratt & whitney. We were warned that this was not good to find in the screen and could be a warning of what might come. This operator did not have a spare Q.E.C. yet and had lots of work lined up for the summer & he decided to press on with this engine. We did about 2 short flights to deliver goods and kept checking screens and it was always about the same amount.

In the downtime I built up another Q.E.C for the aircraft.

Here is the story on the third flight. We took off with a load(heavy) in the aircraft and it was about a 3 hour flight to the destination and the airplane ran great. Offloaded and headed back. There were 3 of us in the airplane, I was sitting right seat to gain knowledge, hours, etc. with the owner sitting in the left seat and the other seasoned pilot in the engineers seat. We were about halfway back to the home base when I felt this shudder . I looked down at the instruments and saw the left torque gauge unwinding like a clock. We tried some quick emergency procedures first but I figured I better get out of the seat and let the seasoned pilots handle the problem. So I headed back to have a look outside. All I could see was oil pouring out of the breather outlets. By the time I returned to the front the oil pressure was going down. They feathered the engine without any problems.

. I looked down at the instruments and saw the left torque gauge unwinding like a clock. We tried some quick emergency procedures first but I figured I better get out of the seat and let the seasoned pilots handle the problem. So I headed back to have a look outside. All I could see was oil pouring out of the breather outlets. By the time I returned to the front the oil pressure was going down. They feathered the engine without any problems.

About an hour or so later we were back on the ground. After we landed I got out and gave the left feathered prop a wiggle and it was locked up solid. Found tons of silver in the sump,screens, etc. after I removed the engine off of the the airplane.

I have since learned sometimes when the 2800 fails a front main bearing all of those parts go forward into the front scavenge pump and it fails. This pump also drives the gears for the torque system. It also pumps the oil back to the rear of the engine. I am sure that's why I saw oil pouring out the breather, the engine could no longer scavenge the oil from the front to the back.

I hope this story helps.

WW

Once upon a time I had the pleasure to do some pilot/mechanic work for an operator of a twin R-2800 powered aircraft during one summer. He had been getting small amounts of metal out of the left engine, it was mainly silver with copper on the back which is main bearing, master rod bearing, etc. on a pratt & whitney. We were warned that this was not good to find in the screen and could be a warning of what might come. This operator did not have a spare Q.E.C. yet and had lots of work lined up for the summer & he decided to press on with this engine. We did about 2 short flights to deliver goods and kept checking screens and it was always about the same amount.

In the downtime I built up another Q.E.C for the aircraft.

Here is the story on the third flight. We took off with a load(heavy) in the aircraft and it was about a 3 hour flight to the destination and the airplane ran great. Offloaded and headed back. There were 3 of us in the airplane, I was sitting right seat to gain knowledge, hours, etc. with the owner sitting in the left seat and the other seasoned pilot in the engineers seat. We were about halfway back to the home base when I felt this shudder

About an hour or so later we were back on the ground. After we landed I got out and gave the left feathered prop a wiggle and it was locked up solid. Found tons of silver in the sump,screens, etc. after I removed the engine off of the the airplane.

I have since learned sometimes when the 2800 fails a front main bearing all of those parts go forward into the front scavenge pump and it fails. This pump also drives the gears for the torque system. It also pumps the oil back to the rear of the engine. I am sure that's why I saw oil pouring out the breather, the engine could no longer scavenge the oil from the front to the back.

I hope this story helps.

WW

Re: Running with Metal

Sun Oct 02, 2011 2:24 am

So how many hours of operation did he get from the engine, after the bearing distress was discovered? Was normal take off power used after the discovery?

Re: Running with Metal

Sun Oct 02, 2011 10:19 am

There is a different viewpoint regarding oil filters.

Many old engines of various types were designed to operate with a large flow of oil. A large volume. This was to enhance splash-lubrication, and conduct heat away from the contacting surfaces.

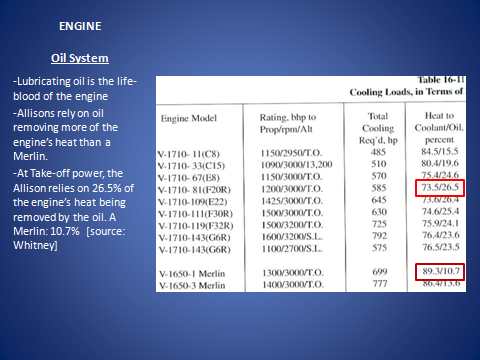

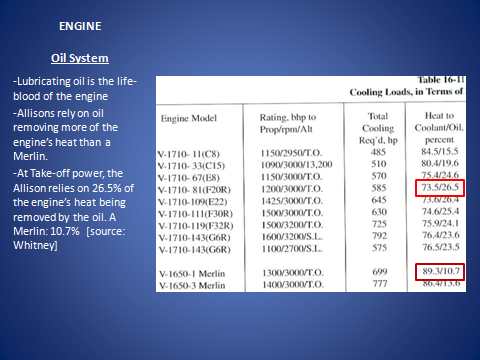

The Allison works like this, as opposed to the Merlin. As you can see in this chart (extracted from my "P-40 Groundschool") the oil system in the Allison is designed to remove more than twice as much heat at high power than a Merlin. Higher volume of flow.

This is not to say one way is better or worse. It's just the way the designing engineers planned it.

Every time you introduce a filter or a screen into a fluid system you reduce it's flow. The pressure doesn't necessarily change, particularly if there is a pressure-regulating valve in the oil pump, but the volume does. Less quantity of oil passing over the contact surfaces in a given time.

This may not be what the designing engineers wanted. They knew about filters. They chose fairly open screens (plus often a magnetic plug).

Adding modern filters to vintage fluid systems may reduce lubricating flow, and not be a perfect fix.

Dave

Many old engines of various types were designed to operate with a large flow of oil. A large volume. This was to enhance splash-lubrication, and conduct heat away from the contacting surfaces.

The Allison works like this, as opposed to the Merlin. As you can see in this chart (extracted from my "P-40 Groundschool") the oil system in the Allison is designed to remove more than twice as much heat at high power than a Merlin. Higher volume of flow.

This is not to say one way is better or worse. It's just the way the designing engineers planned it.

Every time you introduce a filter or a screen into a fluid system you reduce it's flow. The pressure doesn't necessarily change, particularly if there is a pressure-regulating valve in the oil pump, but the volume does. Less quantity of oil passing over the contact surfaces in a given time.

This may not be what the designing engineers wanted. They knew about filters. They chose fairly open screens (plus often a magnetic plug).

Adding modern filters to vintage fluid systems may reduce lubricating flow, and not be a perfect fix.

Dave