Airliner B-29

Tue Oct 20, 2009 1:23 pm

Airliner B-29

The Russian Fortress thread : http://warbirdinformationexchange.org/phpBB2/viewtopic.php?t=32571 contained a great link to how the B-29 became the Tu-4.

What was unknow to me was the Airliner Tu-70 version done in parallel !!!!!

Interesting spin on things you think you know. Great read link provided by rreis:

http://www.airspacemag.com/military-aviation/USSR.html

OK, onto it: http://en.wikipedia.org/wiki/Tupolev_Tu-70

The Russian Fortress thread : http://warbirdinformationexchange.org/phpBB2/viewtopic.php?t=32571 contained a great link to how the B-29 became the Tu-4.

What was unknow to me was the Airliner Tu-70 version done in parallel !!!!!

Interesting spin on things you think you know. Great read link provided by rreis:

http://www.airspacemag.com/military-aviation/USSR.html

OK, onto it: http://en.wikipedia.org/wiki/Tupolev_Tu-70

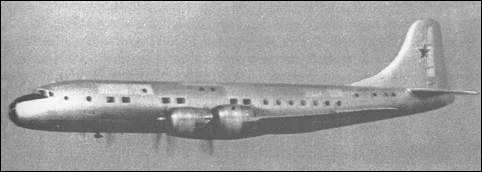

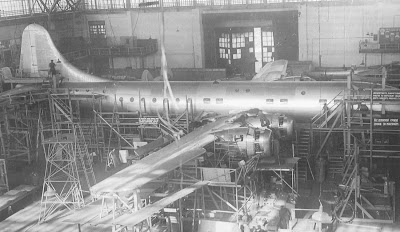

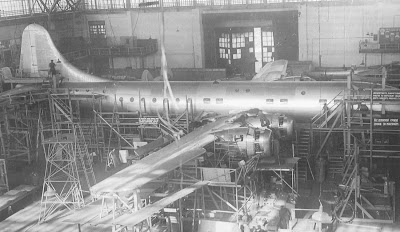

The Tupolev Tu-70 was a Soviet passenger variant of the Tu-4 bomber designed immediately after the end of World War II. It used a number of components from Boeing B-29s that had force-landed in the Soviet Union while bombing Japan. It had the first pressurized fuselage in the Soviet Union and first flew on 27 November 1946.[1] The aircraft was successfully tested, recommended for serial production, but ultimately not produced because of more pressing military orders and because Aeroflot had no requirement for such an aircraft.

Tue Oct 20, 2009 3:30 pm

Questions:

1) Did the passengers have to ride a trolley in a tube to get from the front to the back?

2) How long would those square windows have lasted in service? Think DeHavilland Comet crashes from cracks in the square window frames.

1) Did the passengers have to ride a trolley in a tube to get from the front to the back?

2) How long would those square windows have lasted in service? Think DeHavilland Comet crashes from cracks in the square window frames.

Tue Oct 20, 2009 3:39 pm

That is pretty funny. In the photos.,. it looks like they kept the B-29 nose cone!!! This way, it could be converted back into a bomber? HAH!

Cool links. Thanks!

Cool links. Thanks!

Tue Oct 20, 2009 3:56 pm

A lot of parts where canibalized from B-29's to get it in the air.

Tue Oct 20, 2009 4:19 pm

It would be interesting to see the seating arrangement in that thing. I see windows up where the life raft doors used to be, so I wonder if they somehow installed seats up there as well? Maybe sleeping quarters? It's pretty low clearance up there though.

Tue Oct 20, 2009 5:27 pm

bdk wrote:Questions:

1) Did the passengers have to ride a trolley in a tube to get from the front to the back?

2) How long would those square windows have lasted in service? Think DeHavilland Comet crashes from cracks in the square window frames.

Almost looks to be pressurized in the cockpit area, non-pressurized in the middle and then pressurized again behind the wing.

Tue Oct 20, 2009 6:31 pm

mustanglover wrote:bdk wrote:Questions:

1) Did the passengers have to ride a trolley in a tube to get from the front to the back?

2) How long would those square windows have lasted in service? Think DeHavilland Comet crashes from cracks in the square window frames.

Almost looks to be pressurized in the cockpit area, non-pressurized in the middle and then pressurized again behind the wing.

That's how it is on the B-29, so that makes sense.

Tue Oct 20, 2009 6:39 pm

So you pay extra for the seats in the pressurized area? I guess you just take a nap during the flight in the cheap seats (due to hypoxia).

Tue Oct 20, 2009 7:06 pm

bdk wrote:2) How long would those square windows have lasted in service? Think DeHavilland Comet crashes from cracks in the square window frames.

Actually the crack on G-ALYP developed from a ADF aperture in the roof, and because it's the same structure and shape as a conventional window, it's often cited as such. A minor point, but worth being precise?

And strictly speaking the metal fatigue in the Yoke Peter case was not caused by the shape of the windows, but by a change from the designed glued construction to riveting, using a punch-rivet construction which increased the possible opportunities for stress cracks to develop.

http://en.wikipedia.org/wiki/BOAC_Fligh ... al_fatigue

Interesting 2006 update to the accident in the link above as well.

Not trying to teach you your business, but the usual shortcuts in the description of the G-ALYP accident don't help, IMHO.

Regards,

Tue Oct 20, 2009 9:46 pm

It would be interesting to see the seating arrangement in that thing. I see windows up where the life raft doors used to be, so I wonder if they somehow installed seats up there as well? Maybe sleeping quarters? It's pretty low clearance up there though.

Mind you Gary, this went from a mid wing arrangement in a B-29 to a low wing mounting on this puppy. More space available ? Hey what do I know

Tue Oct 20, 2009 11:03 pm

JDK wrote:bdk wrote:2) How long would those square windows have lasted in service? Think DeHavilland Comet crashes from cracks in the square window frames.

Actually the crack on G-ALYP developed from a ADF aperture in the roof, and because it's the same structure and shape as a conventional window, it's often cited as such. A minor point, but worth being precise?

And strictly speaking the metal fatigue in the Yoke Peter case was not caused by the shape of the windows, but by a change from the designed glued construction to riveting, using a punch-rivet construction which increased the possible opportunities for stress cracks to develop.

When most of the wreckage was recovered, investigators found that fractures started on the roof, a window then smashed into the back elevators...

...and the forward ADF* aerial window in the cabin roof where the initial fatigue failure occurred...

Even more confusing, your source calls it a window as well!

So the cracks started in the poorly prepared holes, but then migrated to the ADF "aperture" window which then fell out when the aperture cracked/failed and knocked the tail off?

In any case, nobody puts rectangular windows in pressurized structure based upon what was learned from this incident. Fatigue cracks may not have begun at the stress risers caused by the ccorners of the rectangular windows, but the cracks in the skin headed right to the corner of the window where that stress riser was located. It unzipped from there. If there had been a round or elliptical window/aperture, there would have been no loss of the aircraft, even with the inadequately formed holes.

By the way, most of what I learned about this incident came from a British B-Movie, so I certainly wouldn't cast doubts upon that as a source!

Tue Oct 20, 2009 11:15 pm

bdk wrote:When most of the wreckage was recovered, investigators found that fractures started on the roof, a window then smashed into the back elevators......and the forward ADF* aerial window in the cabin roof where the initial fatigue failure occurred...

Even more confusing, your source calls it a window as well!

Yes, hence my 'often cited as such'. But we'd call it an aperture if we were being precise, wouldn't we?

So the cracks started in the poorly prepared holes, but then migrated to the ADF "aperture" window which then fell out when the aperture cracked/failed and knocked the tail off?

That's my understanding, FWIW.

In any case, nobody puts rectangular windows in pressurized structure based upon what was learned from this incident. Fatigue cracks may not have begun at the stress risers caused by the ccorners of the rectangular windows, but the cracks in the skin headed right to the corner of the window where that stress riser was located. It unzipped from there. If there had been a round or elliptical window/aperture, there would have been no loss of the aircraft, even with the inadequately formed holes.

I'd agree with the first part. It is certain that a round window is 'failure proof' in these circumstances? Would they act as crack stoppers?

By the way, most of what I learned about this incident came from a British B-Movie, so I certainly wouldn't cast doubts upon that as a source!

Ah, if that's 'No Highway in the Sky', then you could do worse. Based on the book No Highway by Nevil Shute, full name Nevil Shute Norway and successful aircraft designer. Much is made of him 'predicting' the Comet accidents in his book, which is both correct and not, depending on how you view it. Interesting nonetheless. His autobiography, Slide Rule is well worth reading.

Regards,

Wed Oct 21, 2009 2:24 am

I thought this thread was going to be about the Boeing 377 Stratoliner....

Wed Oct 21, 2009 2:31 am

Back onto the subject of Russian B-29 variants  , don't forget the "improved" versions of the Tu-4 bomber, the Tu-80 and Tu-85.

, don't forget the "improved" versions of the Tu-4 bomber, the Tu-80 and Tu-85.

Here's a couple of links to more info.....................

http://www.aviastar.org/air/russia/tu-80.php

http://www.aviastar.org/air/russia/tu-85.php

Here's a couple of links to more info.....................

http://www.aviastar.org/air/russia/tu-80.php

http://www.aviastar.org/air/russia/tu-85.php

Wed Oct 21, 2009 11:20 am

Certainly not "failure proof." You need good design practices as well. A round window frame that is too thin would most certainly fail too, but it would not have the stress riser affect of the corners of a rectangular window. All other things being the same, the rectangular window would fail far sooner. The technical term is a "stress concentration factor."JDK wrote:It is certain that a round window is 'failure proof' in these circumstances? Would they act as crack stoppers?

(mechanics) A condition in which a stress distribution has high localized stresses; usually induced by an abrupt change in the shape of a member; in the vicinity of notches, holes, changes in diameter of a shaft, and so forth, maximum stress is several times greater than where there is no geometrical discontinuity.

And my favorite resource for everything engineering: http://en.wikipedia.org/wiki/Stress_concentration

There is a reason that cracks are stop drilled with round holes rather than square ones!