Lots more work going on lately but little reporting. I am sorry for that. Right now I am only capable of posting photos for the updates at work and not home and things are so busy at work I do not have the time to make the updates.

So much to do for our upcoming trip across the US to OSH and Topeka and it has been quite the roller coaster ride. Recently three of our donors from Switzerland bailed out of going on the trip after 9 months of saying they were going for sure and will not back out. Mad scramble ensues as the loss of those donations kills the trip. One of our museum patrons has doubled his donation to help cover the loss as we all feel we cannot and will not cancel the trip now. We have WWII PV-2 vets coming to meet us and we will not let them down or the vets who may just happen upon us at one of the shows.

Now I take a closer look at the fuel calculations and sharpen the pencil to see what we really need but frankly the problem is our lack of long range flight experience in 062. We certainly have the book values for consumption rates and fuel flows that have been our guide all along. I have talked to the Glenn at the Hot Stuff gang and Dave who owns Attu Warrior and they have been quite helpful with their numbers but there are big differences in how they operate their Harpoons. Hot Stuff lives in the low lands so they do not have to climb too high and Dave pretty much always does climbs to altitude since they are from Colorado.

We need to be conservative in our calculations but just how conservative is the question when trying to figure out the actual cost of the trip. Right now we have fuel and oil funds to get us to OSH and to Topeka but after that not so much. As I said we all agree that we cannot stop now too many are counting on us so we will continue our fundraising to come up with the remaining funds needed to get home.

Many things have to happen to get 062 ready and one important aspect for me is the capability of lots of extra fuel for that conservative safety factor/comfort level that is desired. Right now our outer wing tanks are not working so we only have the mains and aux tanks which hold just under 500 gallons. 500 gallons do not last long on trips like these so we need more fuel. One of the ways to do this is to explore the other options used in the Harpoon. The PV-2's had a fuselage tank and drop tank capability that would give us an extra three hours of range/safety factor so it is desired to put these in place. Not only will they increase our capability but it makes the old gal more complete and also looks pretty cool. Of course there is a trade off to have the additional drag of the drops but so what. I think a PV-2 looks great with the drops and once they go on the wings I would like to see them stay there. Incidentally I looked in the flight manual to see what the drag penalty is for the drops and the charts say that external stores data will be provided in the future. I sent a text to Lockheed but I haven't heard back yet.

Pretty simple, just find a pair of tanks and pylons and away you go. Yeah right, welcome to warbirds. As with any project on old aircraft, especially Warbirds, one idea created a hundred other headaches that you have to go through to make it happen. Finding the tanks is a big pain in the backsides for several reasons. First they haven't been manufactured in 60 plus years. They are made of steel that likes to rust away. Then there are the hot rod guys who all have dreams of recreating the Lakester racers, you know the ones that were made from drop tanks. This little dream of so many has single handedly consumed a large number of our Warbird drop tanks most of which were cut up and then never finished.

Finding the tanks is easy when compared to finding the pylons to hold them up with. It is amazing to me that they are so difficult to find because many aircraft used the same basic pylon. Lockheed designed this pylon as a universal unit that could be used for drops, bombs and gun pods. They were installed on the P-38, PV-1, PV-2 and the P-61 even that carried 4 of them. With so many of these aircraft having been produced why are they so hard to come by? My best guess is they were needed to supply some foreign country post WWII and off they went. I bet they are sitting in a warehouse in Brazil right now. Oh well.

Dave Hansen was kind enough to trade us one of his pylons as he had two rights. It is great Dave and will be the basis for our right side. The left we will be making from the blueprints and borrowed parts that were kindly loaned to us by some wonderful big name warbird folks. Thank you guys so much for your help with this.

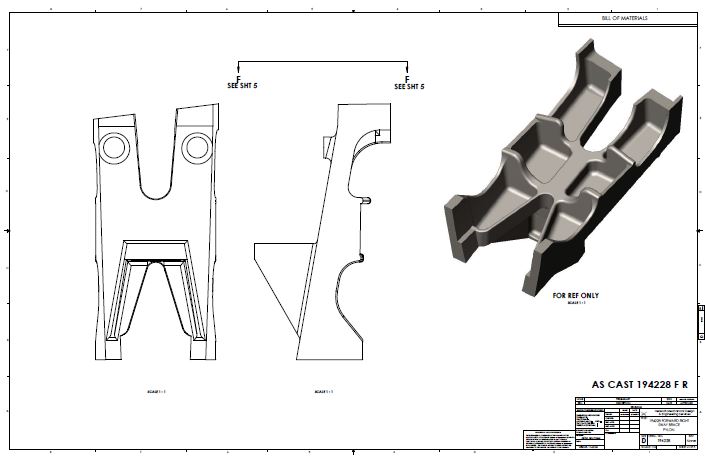

Casting parts for a torpedo sight bracket or other trinkets is a long ways off from making a casting that holds a drop tank on the wing so it is important to get it right. It has to be just as accurate and strong as a wing spar or other structural component so when you have to make something like this you need to use the proper resources.

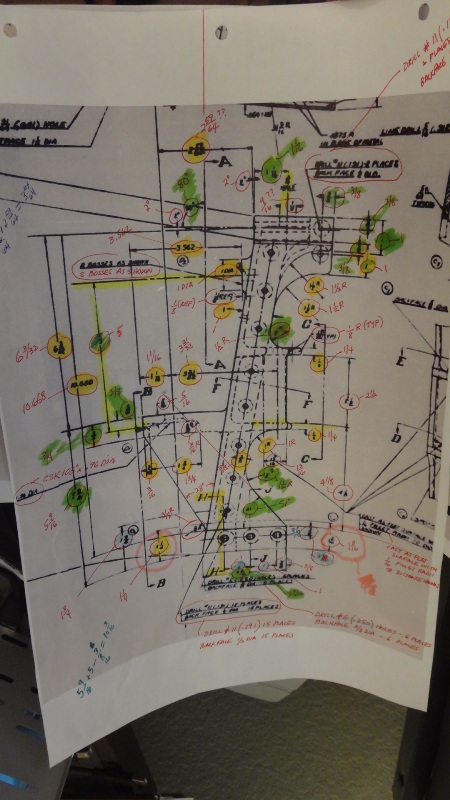

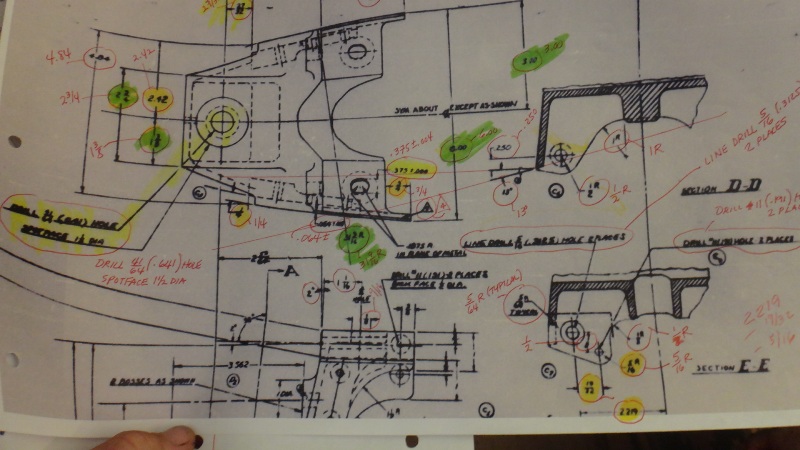

On this project we start with the factory drawings which leave a lot to be desired. Thanks to Bill and Bill at the kind restoration shop who sent me the drawings. As with all of these drawings they are a blessing that we have simply even them but sometimes we feel the need to curse the folks that were taking the microfilm photos at the time. You can have one drawing as crystal clear as it was when the draftsman created it right next to a drawing that is completely illegible for many reasons.

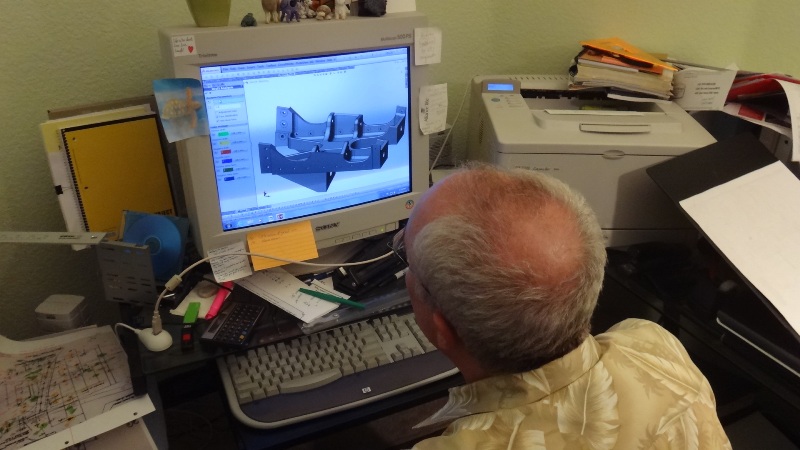

After taking original loaned parts as examples to Manuel, our wonderful engineering volunteer, he began the process to make a 3D model of the parts in solidworks. With the model we have options available to us to have castings made or to have the part machined out of billet. It was difficult for Manuel as the drawings were not production drawings and did not have enough information to model. Thanks to Mike and John at two different restoration shops for loaning us the real parts because these answered the many questions of the missing dimensions. This is so much of a team effort on many different levels.

Here is Manuel with the 3D model he worked on for countless hours.

And here is Tim the machinist figuring out how to make the part. These guys have been invaluable in helping to solve the mystery of the pylons. Projects like these are massive undertakings that involve huge resources in time and money. It ain't cheap to reverse engineer and reproduce parts accurately which is why restorations are so costly. We are fortunate that we have some real nice people helping us and volunteering their time, materials and energy. Thank you all!

Manuel can even do an analysis of the relief angles to be sure the pattern will come out of the sand properly at the foundry. He can also do stress and strain analysis for alternate methods of manufacture.

Back to work on the simple minded things that my pea brain can handle like banging on the airplane.

The leading edges need to come off again for access for pylon mounting and plumbing, wiring and rockets. Where the pylons attach to the wing two of the original studs were simply cut off and the remnants were flush with the skin. I needed to drill these out as they would not budge by normal extraction methods. By drilling them out to almost their full OD it weakens the stud and makes it easier to remove. It is tricky to not broach the wall and possibly damage the structure but I got lucky and it came out nicely.

This allowed me to install the pylon adapter bracket on the right side. This is what the pylon bolts to on the wing and these brackets are specific to the different type of aircraft. We were thankful to have located an original set and we have some extras of one side.

The tubing that connects to the tank was also cut off flush with the wing so Ricky fabricated a new one that you can see coming out of the wing like it is supposed to.

One of the chain of events for making the drop tanks functional is the plumbing. Earlier we replaced the 1943 rubber self sealing hose inside the wing spar with new hose. Now we need to reconnect the drop tank plumbing to the fuel transfer valve. It was disconnected back in its tanker days and now need to be reinstalled with new rubber couplings. Bringing old systems unused since the aircraft was made is a lot of fun and is rewarding.

Earlier we removed the oil tanks to gain access to replace the hoses inside the spar. When you remove the oil tanks it is standard practice to clean them out and remove any sludge that could have built up in the bottom. Sludge is the thick and heavy crud that builds up over time. Tanks are usually set up to allow for room for sludge to accumulate below the outlet fitting. These tanks had some sludge in them but not a lot. A few gallons of avgas and slosh them until the sludge is suspended in the fuel and then drain. You need to repeat this until the tank is clean. The right side cleaned up nicely but the left was another story.

When the left side tank was rinsed the crud on the bottom of the tank started to look like one of the those gold panning shows on TV. Lots of shiny metal in the bottom of the tank. Holy crap our engine has been making metal?!

This didn't jive with everything else we have been seeing though and our oil analysis etc. We had recently changed the oil filters and nothing was present in the filter elements at all. Nothing showed up in the oil analysis except to say that the more time we put on the engines the cleaner they are running so where did the metal come from?

I remembered that at the end of her tanker career she had an engine failure on the left side. They knew the engine was going and were still running it until it really gave up the ghost. It finally did and then the engine was pulled and replaced with another one out of the can. the problem was that the mechanic didn't clean out the whole oil system properly. When you have a failure and the engine makes metal that metal contaminates everything that uses engine oil like the prop, oil cooler, prop governor, oil tank etc. If you don't remove all of this metal then it will flow into your new engine and screw it up too which is just what happened. After they put the new engine on the metal from the old engine killed the new one.

The story goes that it was these two successive engine failures that kept Tanker 101 from making good on her contract with the forestry service and the contract was lost. This loss forced the operator into bankruptcy and he had to fold.

The guy who told me this story was one of his pilots who was laid off as a result. He said that Mr. Kinney owed him a lot of back pay that was now gone from the bankrupt status. He went on to say that several years after this he got a call from Bruce Kinney who said that he now had recovered enough and that he wanted to pay the pilot back for the money he owed him and he did. The pilot was understandably astounded and conveyed how much that meant to him and what a testament it was to the character of Bruce Kenney. Bruce passed away a several years ago.

The metal in our tank was left over from that failure so long ago and had been glued in place by the sludge. Once the avgas went in it washed away the grime and exposed the metal. This is a good example of why non detergent oil is used on old engines like this. If we had used detergent oil then the sludge would have been cleaned somewhat and the metal might have made its way into the engine.

Here is a poor shot of the metal in the bottom of the tank. Needless to say this metal needs to all come out

The other tank cleaned up nicely but this one will have to have the sump removed and the tank more thoroughly cleaned. At this point I remembered that we had bought some oil tanks with a large PV-2 parts inventory we had picked up a while ago. I went and found the tanks in storage and sure enough we had a new old stock pair of beautiful tanks complete with all of the fittings and new oil quantity sending units.

Happiness is a new pair of oil tanks right Ricky?

We even have replacement sets of oil filler necks/vent assys with caps

This saves us a large amount of time in just cleaning up the old tanks and prepping them for reinstallation. The old ones are perfectly good but the new ones are decidedly better.

Here is Cousin mike working on the drop tank and cabin tank fuel lines and couplings in the gear well.

Yesterday we had a great work day with lots of folks showing up to help. Dick was working on wiring in the wing getting the landing lights working. Ricky fixed a problematic up lock cylinder that has persisted in leaking lately.

Mark finished up the wiring for the ARC-5 Command set and he fired it up for the first time. Dynamotors were spinning and I heard audio through the headphones! Another radio set comes to life. How cool is that. Just in time too because we have a PV-2 radio operator meeting us at topeka. Hopefully we can get the ARB running with the ART-13 so he can broadcast once again from his old office.

Ricky's kids were helping with cleaning duties. Ken and his kids were making PX things to sell at Oshkosh to help us raise money for the gas to get home.

It was a good day yesterday and now I need to get away from the computer and get back to work. We have a big trip coming up. Well half of it anyway!