Gentlemen (and Jeff)

I'm re-skinning an all metal set of elevator trim tabs for my project Stearman (early ones were metal, later ones wood) but I've hit a bit of a snag: how to buck the rivets in the tab that run down the leading edge. I have several bent and battered tabs and the ones that appear to be original are all riveted with a mixture of regular, old, 1/8 and 3/32 AN455 Brazier head AD rivets (1/8 where the hinges attach, 3/32 where they don't). I just know that some little old gray haired Wichita sheet metal wizard who long ago went to his reward had a way to do this that was simple and fast, but I'm stuck. Anybody got any ideas? I know there's a lot of talent and experience here on the WIX board so I'm throwing this out there. See the pics below.

This is the new left hand tab going together, top view. I've stuck a few extra clecos in it so you can see where the sizes change (not that that matters a whole lot). The solid end pieces go in last after the leading edge is buttoned up.

Bottom of new tab - note how the rivets won't penetrate both skins on the leading edge.

Looking down the inside of the tab.

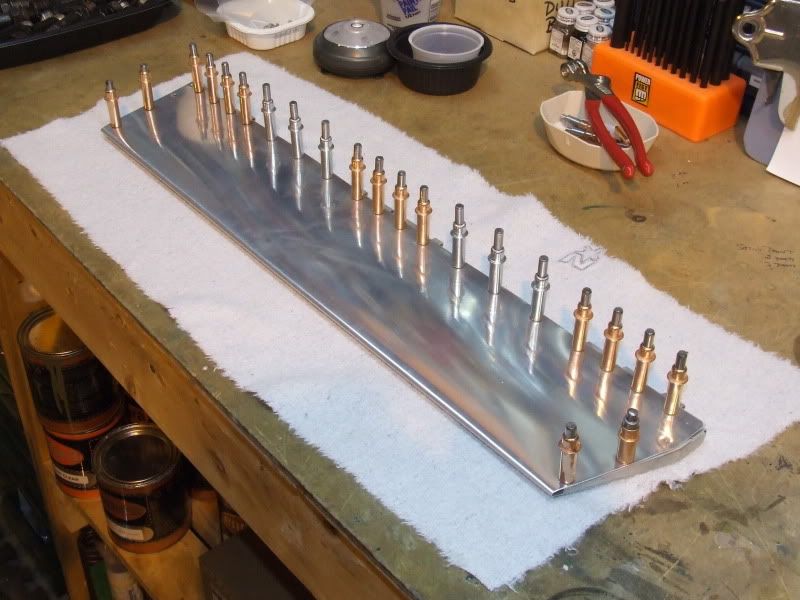

An original tab with standard AN 455 Brazier head AD rivets.

Bottom view of the original tab.

If anyone has got any ideas I'd sure appreciate hearing from you. I know the answer has to be simple - Boeing made thousands of these things - but I'm stumped. My one caveat is that it has to be done the way that it was done originally, so no Cherries or pop rivets allowed! A squeezer would work great, but I'm not aware of one long enough or skinny enough to fit. If anyone is just lurking and doesn't want to post their advice please just email me at

warbirds@shaw.cathanks,

Dan