Let's say I wanted to build a B-24 nose

Thu Mar 10, 2011 10:55 am

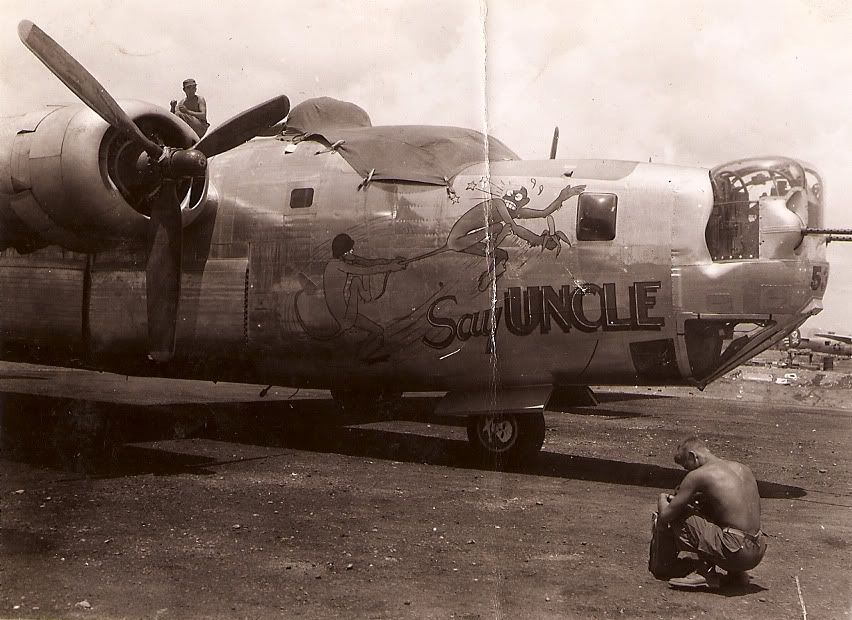

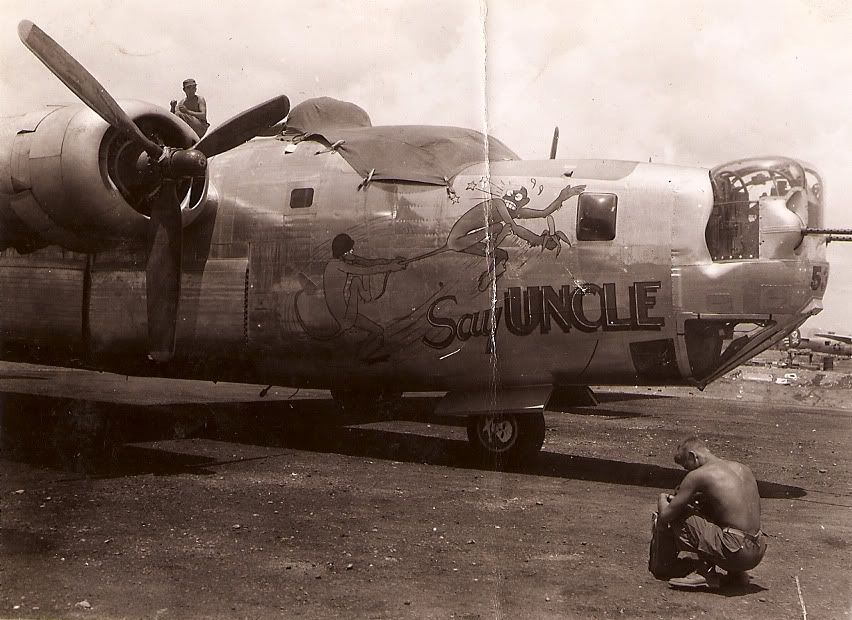

Alright, so I've been hung up on 'Cocktail Hour' ever since I first saw this pic and I feel like this thing needs to be made real again

I'm thinking the whole nose would be a bit too cumbersome to deal with but a decent sized section would be neat. Say, from the cockpit window sill down to where the skin starts to turn under the belly and forward to where the turret starts (give or take). You know, a nose art-sized hunk of airplane.

Now I've seen large hunks of fake bomber for sale before, like these guys sell

http://www.warbirdcollections.com/flak-bait.html

...But I want to use metal because I'd have a hell of a time polishing fibreglass (plus, where would I make the mould?). Anyone know where I could start on a project like this? Surely there are drawings out there somewhere...

-Tim

I'm thinking the whole nose would be a bit too cumbersome to deal with but a decent sized section would be neat. Say, from the cockpit window sill down to where the skin starts to turn under the belly and forward to where the turret starts (give or take). You know, a nose art-sized hunk of airplane.

Now I've seen large hunks of fake bomber for sale before, like these guys sell

http://www.warbirdcollections.com/flak-bait.html

...But I want to use metal because I'd have a hell of a time polishing fibreglass (plus, where would I make the mould?). Anyone know where I could start on a project like this? Surely there are drawings out there somewhere...

-Tim

Re: Let's say I wanted to build a B-24 nose

Thu Mar 10, 2011 11:51 am

years ago in a&p school we had to make small skin sections. buy sheet aluminum, put a slight radius on it. free form some inner curved braces. buy real rivets not the pop type and make rows like the real plane had.. it doesnt have to look perfect. battle /build scars are great and all realism to the project. then paint it. post pics of the process. looks like it could be a fun project. dont get caught up in exact scale panels.. make it look like it came from a wreck or the breakers.

Re: Let's say I wanted to build a B-24 nose

Thu Mar 10, 2011 12:46 pm

Gary Valesco has done this: http://fightingcolors.com/Companypageimages/b-24j_hull_panel.htm

Now they just have to build the rest of the nose!

Now they just have to build the rest of the nose!

Re: Let's say I wanted to build a B-24 nose

Thu Mar 10, 2011 2:04 pm

Anyone who has a high-res colour shot of this nose-art?

Re: Let's say I wanted to build a B-24 nose

Thu Mar 10, 2011 2:08 pm

Warbird Kid wrote:Gary Valesco has done this: http://fightingcolors.com/Companypageimages/b-24j_hull_panel.htm

Now they just have to build the rest of the nose!

Wow.., impressive.

I wonder who in the heck would spend $12K on a fake B-24 nose?

I think I would invest in an ostrich farm first.

Re: Let's say I wanted to build a B-24 nose

Thu Mar 10, 2011 2:29 pm

Yeah, Ill go out on a limb and say 12g is a little high for my own tastes but heck, Gary can pretty much name his own price. I'd love to eventually have something to that affect. Would be nice to honor my grandfather.

The Whole D@mn Thing........

And heres one more for good luck:

The Whole D@mn Thing........

And heres one more for good luck:

Re: Let's say I wanted to build a B-24 nose

Thu Mar 10, 2011 2:45 pm

So yeah, I want to do exactly what Gary Valesco did. The structure on the 'inside' of the panel is even simpler than I thought, too. If accuracy is what I want, should I be looking for drawings or should I be scheduling a trip to my nearest B-24 to take measurements and sections?

-Tim

-Tim

Re: Let's say I wanted to build a B-24 nose

Thu Mar 10, 2011 2:55 pm

Nothing wrong with honoring your grandfather.., but my grandfather would wollop me over the head with his cane for spending that on a fabricated nose section.

Not to take away from the artwork on that panel.., incredible.., but jeeeeesh.

Not to take away from the artwork on that panel.., incredible.., but jeeeeesh.

Re: Let's say I wanted to build a B-24 nose

Sun Mar 13, 2011 1:35 am

Cool Deal,

The simplist way would be to travel to the closest B-24 and take your measurments. NASM might have the drawings but it would be on many rolls of film and it would cost alot to purchase them. Plus once you have them, you would have to use a viewer to see them.

You could also scale the size off of a plastic scale model, and save you the trip. Either way, it is not a small piece of aluminum.

Aircraft Spruce.com will have all of the construction materials that you would need.

A side note, My Grandfather was an A/C on B-24 in CBI. He was in the 10AF 493BG 7thBS.

Good luck with your project.

Bill

The simplist way would be to travel to the closest B-24 and take your measurments. NASM might have the drawings but it would be on many rolls of film and it would cost alot to purchase them. Plus once you have them, you would have to use a viewer to see them.

You could also scale the size off of a plastic scale model, and save you the trip. Either way, it is not a small piece of aluminum.

Aircraft Spruce.com will have all of the construction materials that you would need.

A side note, My Grandfather was an A/C on B-24 in CBI. He was in the 10AF 493BG 7thBS.

Good luck with your project.

Bill

Re: Let's say I wanted to build a B-24 nose

Sun Mar 13, 2011 9:42 am

Bill, I hadn't thought of scaling up from a model but that makes the most sense. I'd probably also want to get in touch with someone who has access to the real deal so I can have pictures of every little detail. With regards to materials, while I'm all for the use of proper solid aircraft rivets, I think I'd save some serious money if the aluminum itself was just locally bought architectural grade.

Looks like I'll be ordering in a model B-24 now. Would Monogram's 1/48 J-model be pretty accurate?

-Tim

Looks like I'll be ordering in a model B-24 now. Would Monogram's 1/48 J-model be pretty accurate?

-Tim

Re: Let's say I wanted to build a B-24 nose

Sun Mar 13, 2011 10:42 am

Your best bet if you want to scale up a model would be to start with GPM's or Fly's Paper model of a B-24 http://www.papermodelstore.com/advanced_search_result.php?keywords=liberator&x=0&y=0 as the formers and surface development are already done for you. You'll just need to scale them up.

Re: Let's say I wanted to build a B-24 nose

Sun Mar 13, 2011 11:06 am

Tim, I've actually used model kits to scale up items for the 1/1 version. It does work, especially as a backup to measurements that you already have. The Monogram kit will work just fine should you decide to use it as an engineering tool. As a bonus the Monogram J has the proper window arrangement for a replica of Cocktail Hour.

The interior of a Liberator nose is a busy place even if you eliminate everything but the stringers and formers. Interior photos would be most helpful for your project.

Scott

The interior of a Liberator nose is a busy place even if you eliminate everything but the stringers and formers. Interior photos would be most helpful for your project.

Scott

Re: Let's say I wanted to build a B-24 nose

Sun Mar 13, 2011 1:10 pm

Thanks for the link, Shrike. I think I'm going to go ahead and scale up from a plastic modelc as paper models never look quite right to me (says the stick and tissue builder).

Scott, it's good to know the average plastic model is good enough to scale from. I lurk on the wooden boat forum and it seems building up from a half hull model was once a popular way to design boats. The same principles of scaling should apply to a B-24 too. I think it's just a (simple?) matter of taking measurements, plotting formers, lofting then building temporary frames to use as a jig. It seems like it's well within what can be done in a basement or garage.

-Tim

Scott, it's good to know the average plastic model is good enough to scale from. I lurk on the wooden boat forum and it seems building up from a half hull model was once a popular way to design boats. The same principles of scaling should apply to a B-24 too. I think it's just a (simple?) matter of taking measurements, plotting formers, lofting then building temporary frames to use as a jig. It seems like it's well within what can be done in a basement or garage.

-Tim

Re: Let's say I wanted to build a B-24 nose

Sun Mar 13, 2011 9:20 pm

Hi,

My guess would be that the original skin material is .040" thick 2024-T3 aluminum. If you go with another grade, I would consider, 6061-T6 or 5052 half hard aluminum. Any material that is not tempared "O" or 3003 aluminum, would be easier to form, but harder to rivet.

The rivet size should be a -4 (1/8") dia and the length is determined by the material thickness. On the left hand side of the B-24 fusalage, there is a fire extinguisher access door. The door assembly is very similar to the one used on the left side panel, rear cockpit, on a North American T-6. You could make one up easy enough, but they are common to find, I would do some looking and you might come up with one. Lance aircraft in Texas or Banaire in CA might have a door assembly that you could pick up cheap.

Please keep us posted on your progress.

Cheers,

Bill

My guess would be that the original skin material is .040" thick 2024-T3 aluminum. If you go with another grade, I would consider, 6061-T6 or 5052 half hard aluminum. Any material that is not tempared "O" or 3003 aluminum, would be easier to form, but harder to rivet.

The rivet size should be a -4 (1/8") dia and the length is determined by the material thickness. On the left hand side of the B-24 fusalage, there is a fire extinguisher access door. The door assembly is very similar to the one used on the left side panel, rear cockpit, on a North American T-6. You could make one up easy enough, but they are common to find, I would do some looking and you might come up with one. Lance aircraft in Texas or Banaire in CA might have a door assembly that you could pick up cheap.

Please keep us posted on your progress.

Cheers,

Bill

Re: Let's say I wanted to build a B-24 nose

Thu Mar 17, 2011 12:17 pm

Probably the easiest way to do it would be to build a buck from lumber the way rare car bodies are made/reproduced, then use that to form the skin & attach it to the wood buck.

Look here:

https://www.tinmantech.com/html/ferrari4.php

& here:

https://www.tinmantech.com/html/ferrari5.php

The piece with the nose art is fairly flat (ish) so the buck wouldn't have to be too thick, maybe 18inches or so to allow for some curvature?

Look here:

https://www.tinmantech.com/html/ferrari4.php

& here:

https://www.tinmantech.com/html/ferrari5.php

The piece with the nose art is fairly flat (ish) so the buck wouldn't have to be too thick, maybe 18inches or so to allow for some curvature?