I've been wandering around from one end of the project to the other tinkering on little parts of it.

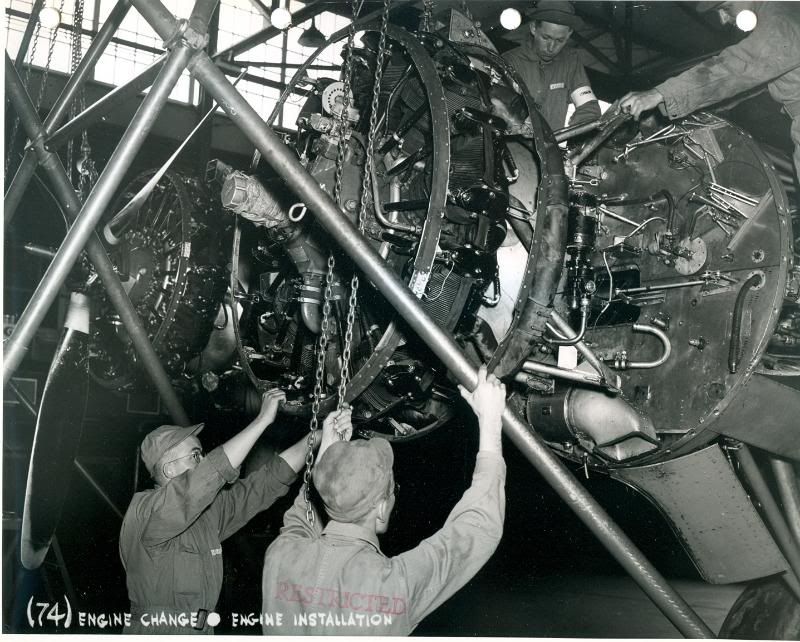

The cowling mountings have been giving me a headache so I just copied the original design. The three-segment ring cowl on the original attaches to two supports on the engine and "floats" with the engine, not being attached to the sheetmetal of the nacelle. The aft one is the aft dishpan or baffle and the front is a ring that attaches to the ends of the cylinders at the rocker boxes. You can see them on this photo of a Y1B-17 in the engine change class at Amarillo:

The hard part on the model is keeping the gap between the rear of the ring cowl and the nacelle. On the original there are no cowl flaps, only an opening to dump the cooling air all the way around the cowling. I simply made the forward ring out of safety wire and attached it into the cowlings. Now the engines can be mounted to the firewall and the cowls can be slipped over the engines and secured during the final assembly. By installing the wire support I keep the engine centered in the cowl and will have the gap so that light will show through the cylinders when looking into the front of the cowls, just like on the original.

On the back end of the airplane I fabbed up the tailwheel fork. The Y1Bs used a standard double-fork design and an entirely different tire and wheel than all the later airplanes. I made the tire by casting a C-47 tire/wheel and then gluing two resin sections together to get the wider tire I needed for the '17. The fork and strut are just aluminum pieces and the axle (.020 safety wire) will eventually have a bolt/nut combo on the ends. The fork will slide up into another strut tube that I'll fabricate and attach to the horizontal stabilizer inside the fuselage. There was a leather boot surrounding the strut (you can see it hanging down in the photo of the original) so I won't be forced to scratchbuild the entire assembly.

Scott